The Welding procedures of Electrofusion Machine and Butt Fusion Machine for PE pipes

- Share

- Issue Time

- Aug 12,2022

Summary

The basic difference between the electrofusion welding process and the butt welding technique.

There are numerous joining techniques and processes for polyethylene (PE) pipes. We at Welping manufacture controllers and machines that support electrofusion and butt welding.

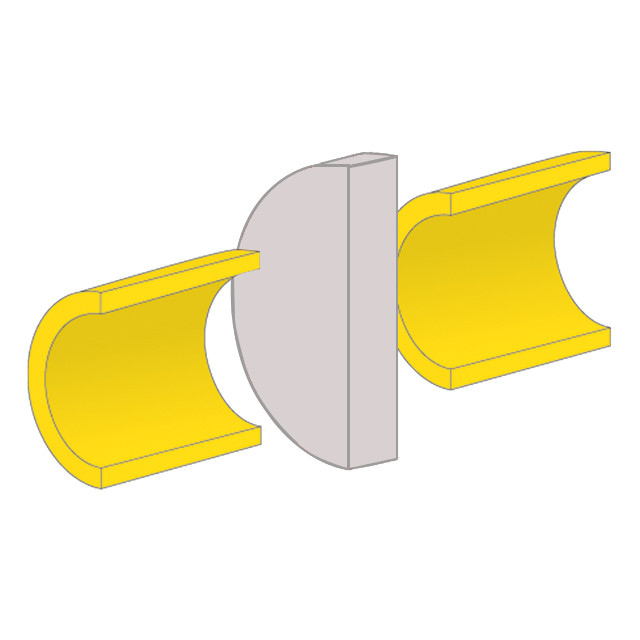

Both processes require special equipment and machines to successfully join two pipes together. The basic difference between the electrofusion welding process and the butt welding technique is that electrofusion welding uses fittings (couplers / saddles) which become an integral part of the PE pipe after successful welding. No additional fittings are required for the butt welding technique. Here the pipes are connected directly to each other.

Electrofusion Welding

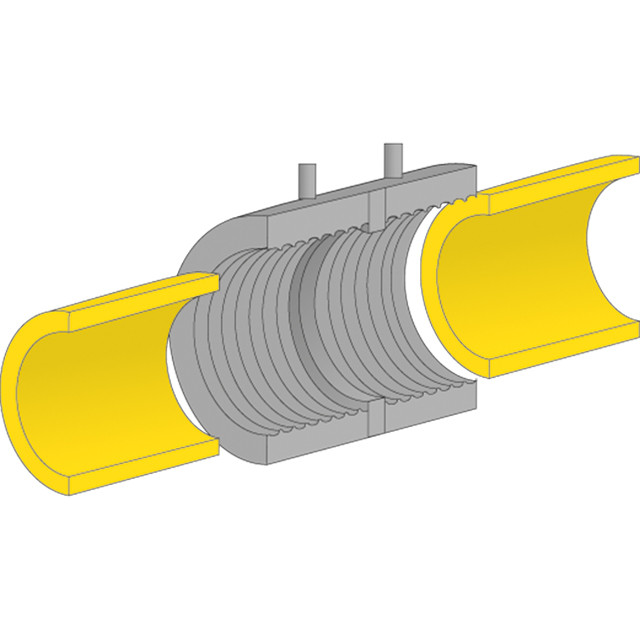

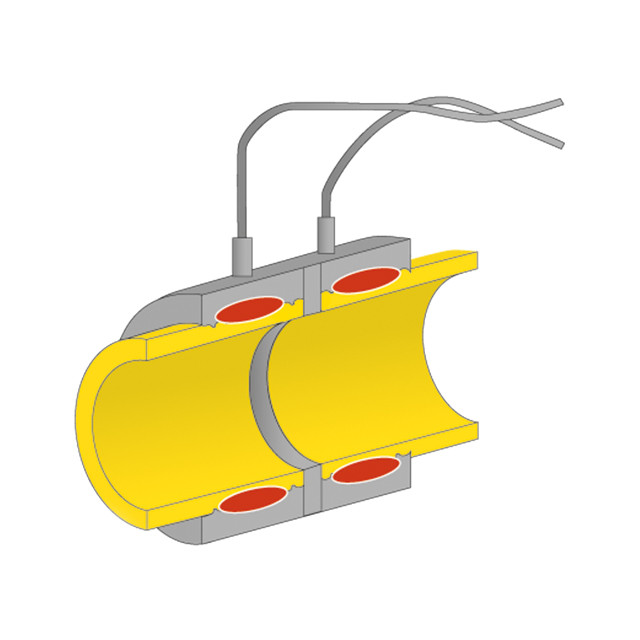

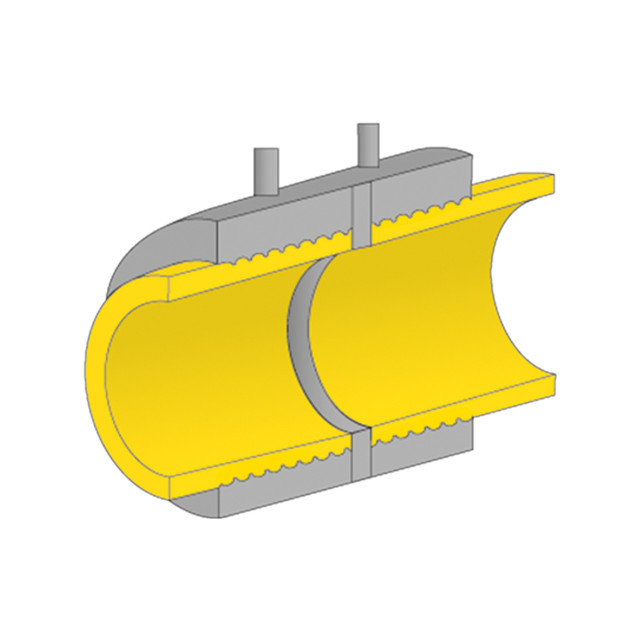

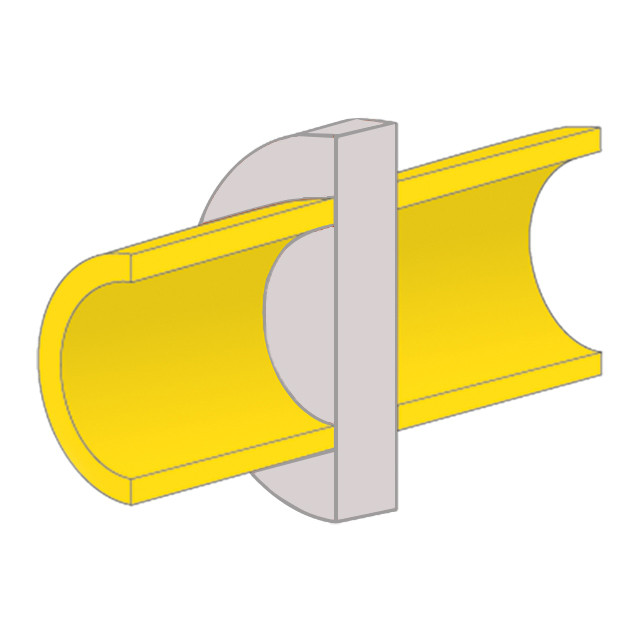

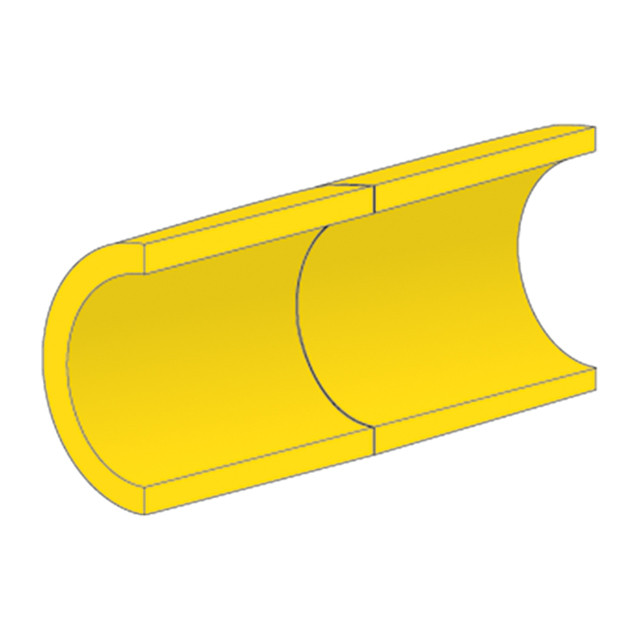

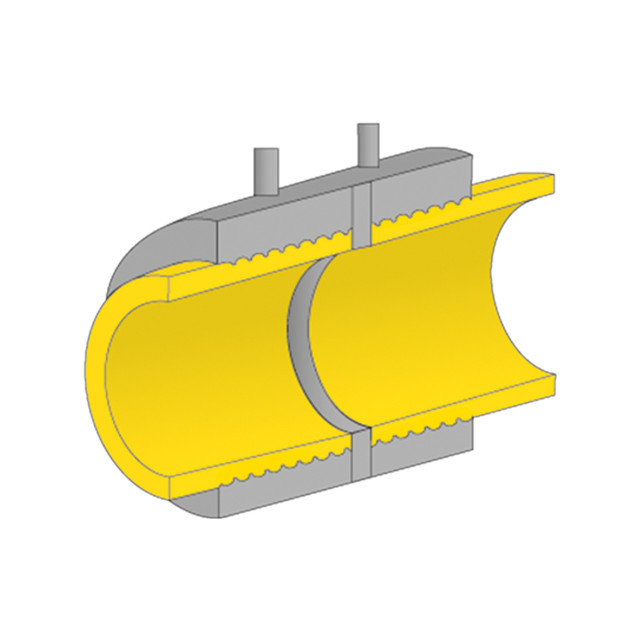

In electrofusion welding, a coupler (electrofusion fitting) is placed over the joint at the peeled and cleaned joint of two pipe ends.

The electrofusion control unit energizes the heating coil integrated in the electrofusion coupler. This heats up the plastic in the welding zone to such an extent that it melts.

At the end of the material and product-specific welding time, the welding zone cools down again below the melting point of the plastic. The fitting and the pipe parts are inseparably fused together and form a gas-tight connection.