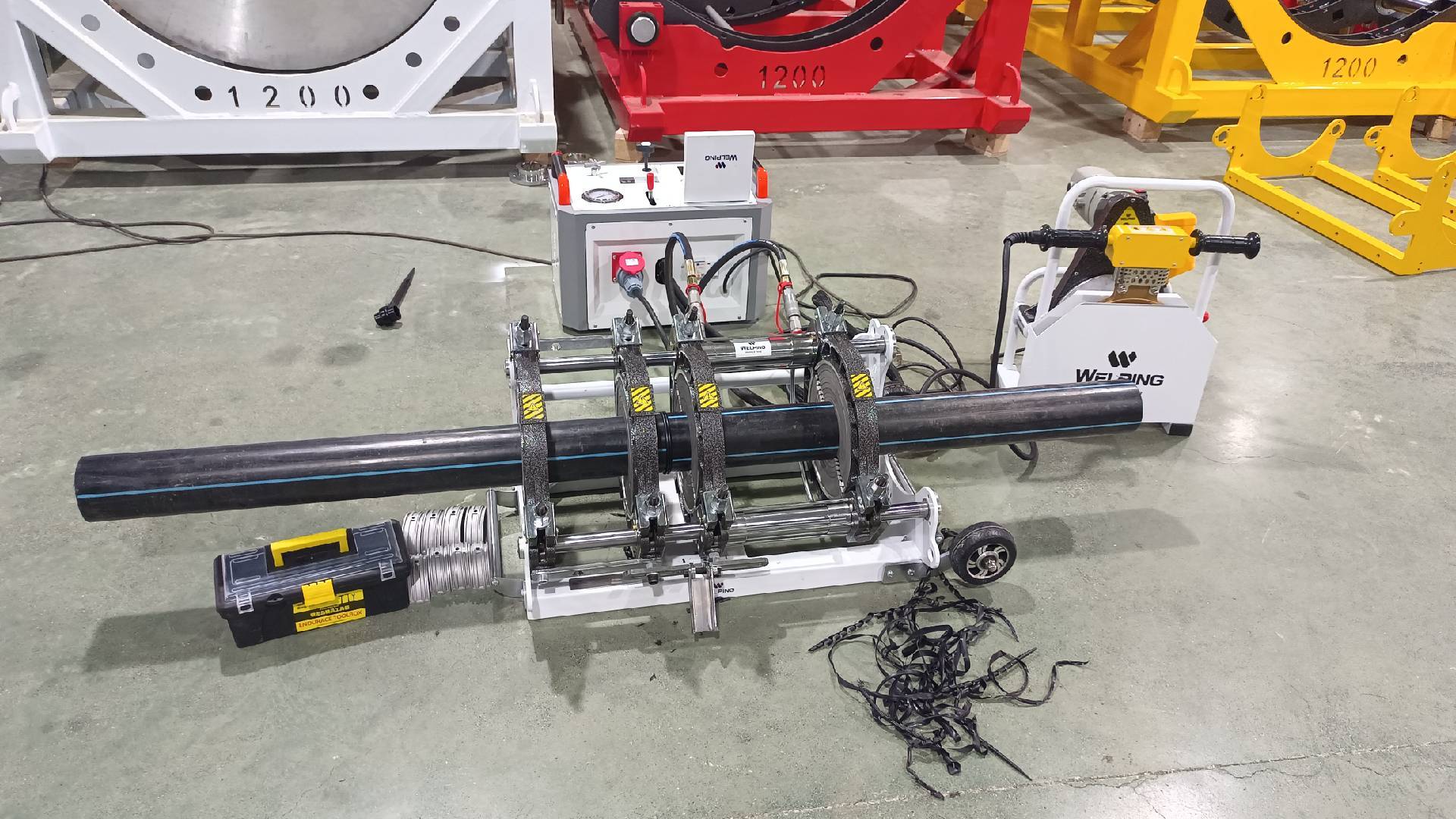

What problems can the upgraded butt welding machine solve in construction?

- Share

- From

- Welping

- publisher

- Ella

- Issue Time

- May 22,2024

Summary

Are you still troubled by these problems.All these problems can be solved by Welping butt welding machine!

Unstable power supply problem leads to the butt welding can not work properly, poor welding effect.

Poor welding quality, cracks, slag entrapment, etc.

Equipment failure, unstable welding current, hydraulic system oil leakage, contactor failure, etc.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||