Various pipe forms after welding by heat fusion butt welding machine

- Share

- From

- Welping

- publisher

- Armstong Tom

- Issue Time

- Jun 25,2024

Summary

The article gives examples of various unsuccessful pipe welding results and the reasons for their formation.

Some customers, after using our heat fusion butt welder, although finally also welded two pipes together, but such welding effect is not up to standard, later in the use of the pipeline process may appear leakage or solidity is not enough.

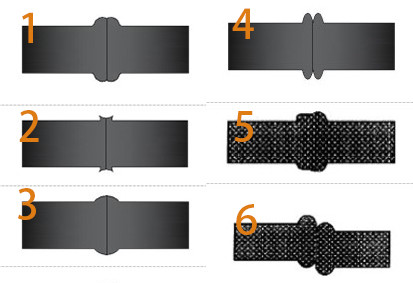

However, it is possible to judge the success of a weld by observing the flanges formed after welding the pipe. The following shows the flanges formed by a successful weld, as well as the shape of the flanges formed by several common types of faulty welds.

1.This round bead, it's a successful weld.

2.Narrow and fall bead.This is caused by too much pressure during welding.

3.Too small bead. Pressure is not enough while welding.

4.There is a noticeable gap between the welding beads, either because the welding temperature has not been reached or the change-over time has been too long and the end of the pipe has cooled down.

5.High & low bead. Different heating time or fusion temperature causes that.

6.This occurs because the pipes are not aligned during welding and deviate by more than 10 per cent of the wall thickness.

Once the user has a good understanding of the welded pipe, the welding beads can be used to check for problems arising from the welding and to correct them.