Fusion Welding Practice with WP500A Pro at Welping Workshop

- Share

- publisher

- Eve Jin

- Issue Time

- Jul 31,2025

Summary

1.At Welping, innovation isn't confined to the drawing board. Beyond R&D and continuous improvement, we believe in the power of practical experience. To truly understand our customers' needs and challenges, the Welping team regularly steps onto the shop floor. This time, we put our flagship machine, the WP500A Pro, to the test in a comprehensive, real-world welding demonstration on 315mm pipe sections. Join us as we document the journey from setup to seamless fusion.

At Welping, innovation isn't confined to the drawing board. Beyond R&D and continuous improvement, we believe in the power of practical experience. To truly understand our customers' needs and challenges, the Welping team regularly steps onto the shop floor. This time, we put our flagship machine, the WP500A Pro, to the test in a comprehensive, real-world welding demonstration on 315mm pipe sections. Join us as we document the journey from setup to seamless fusion.

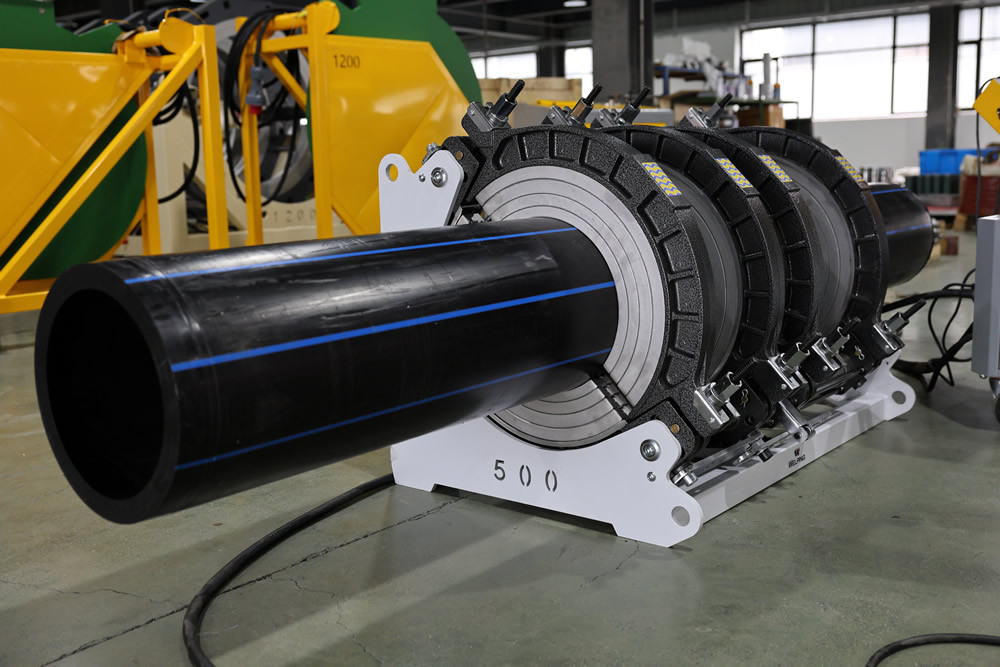

1.The WP500A Pro & Data Logger Duo

• Compact Structure, Reliable Performance: The WP500A Pro features a simple design and delivers stable, durable operation.

• Single-Operator Efficiency: Core welding procedures are easily managed by just one operator.

• Compliant Data Logging: Equipped with a standard data logger that monitors and records critical welding parameters (temperature, pressure, time) in real-time, ensuring compliance with ISO standards.

• Ideal Application: Specifically designed for routine welding operations on medium-diameter HDPE pipelines.

2.The Welding Process | Fluid Execution, Step by Step

Witnessing the WP500A Pro in action is a testament to engineered precision. Here's how the seamless process unfolded:

1. Clamping the Pipes: The intelligent clamping system ensures swift adjustment to the 315mm size and exceptional stability during positioning.

2. Facing the Ends: The integrated facing tool delivers clean, precise cuts, resulting in a visibly smooth surface finish.

3. Heating Phase: The heating plate provides exceptional temperature control and consistency, achieving rapid heat-up times.

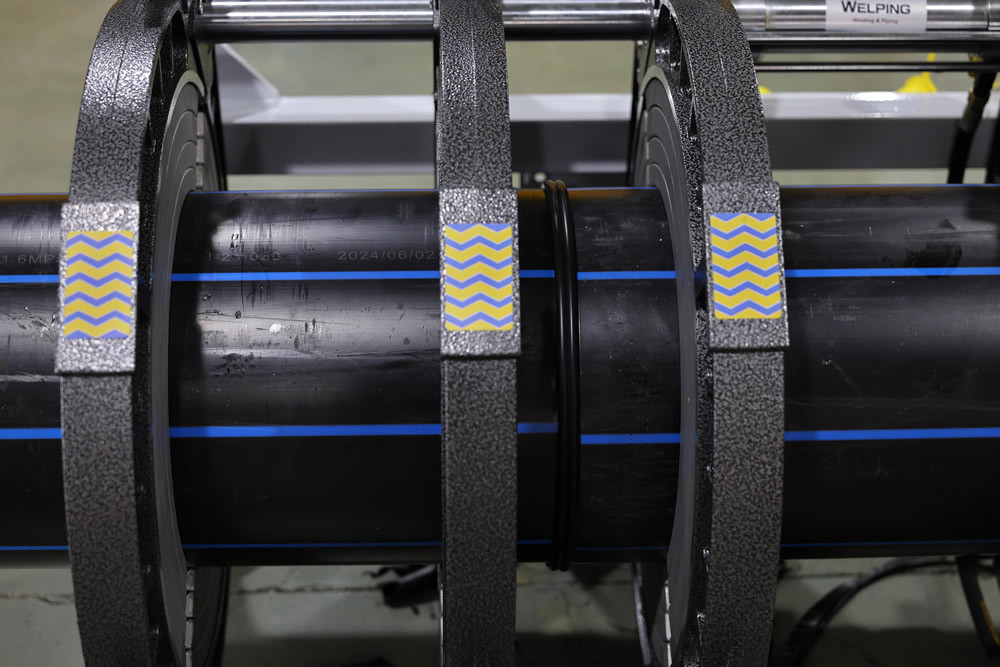

4. Pressure Fusion: Smooth and consistent hydraulic operation delivers a perfectly uniform weld bead.

5. Cooling & Hold: The machine maintains consistent pressure throughout the cooling cycle, ensuring optimal joint integrity.

3.Smart Integration | Complete Parameter Logging

Real-Time Monitoring: Continuously displays temperature, pressure, and time during the weld cycle.

Automated Reporting: Automatically generates a comprehensive weld report for easy traceability and quality records.

User-Friendly Interface: Features an intuitive, easy-to-use interface requiring minimal training.

4.Success Sealed, Smiles All Around

"Every successful weld reinforces our commitment to quality;

Every hands-on test deepens our promise to understand the customer experience."

This demonstration wasn't just about showing a machine; it was about validating the WELPING philosophy. We stand firmly by our principle of "Building with Confidence" . Every Welping welder, including the WP500A Pro, undergoes rigorous testing and validation by our own team. Why? Because we don't just manufacture equipment; we immerse ourselves in the user's perspective, constantly striving to deliver solutions that empower success on the frontline.