Beyond Skill: How Full Automation is Solving HDPE Welding's Biggest Challenges

- Share

- Issue Time

- Sep 11,2025

Summary

Full automation is redefining HDPE welding. It removes human error, ensures precise control, and generates digital records. With faster cycles, fewer reworks, and real-time monitoring, automated welding delivers stronger pipelines and higher efficiency—giving projects a clear competitive edge.

Let’s be honest: the strength of an entire HDPE pipeline hinges on one thing—the quality of its welds. One weak joint can lead to leaks, shutdowns, and expensive repairs. For years, the industry has relied heavily on the expertise of welders. But what happens when human skill isn’t enough?

The Limits of Traditional Welding

Manual and semi-automatic welding come with real-world problems. First, there’s the “human factor.” Even the best welder can have an off day. Fatigue, distraction, or slight misjudgment can introduce flaws into a weld. Second, there’s the “data gap.” If you ever need to find a specific welding parameter from last month's paper records, it can be incredibly difficult. Good luck with that. Finally, efficiency suffers. Inconsistent speeds, reworks, and training new welders all slow projects down.

The Rise of Fully Automatic Welding

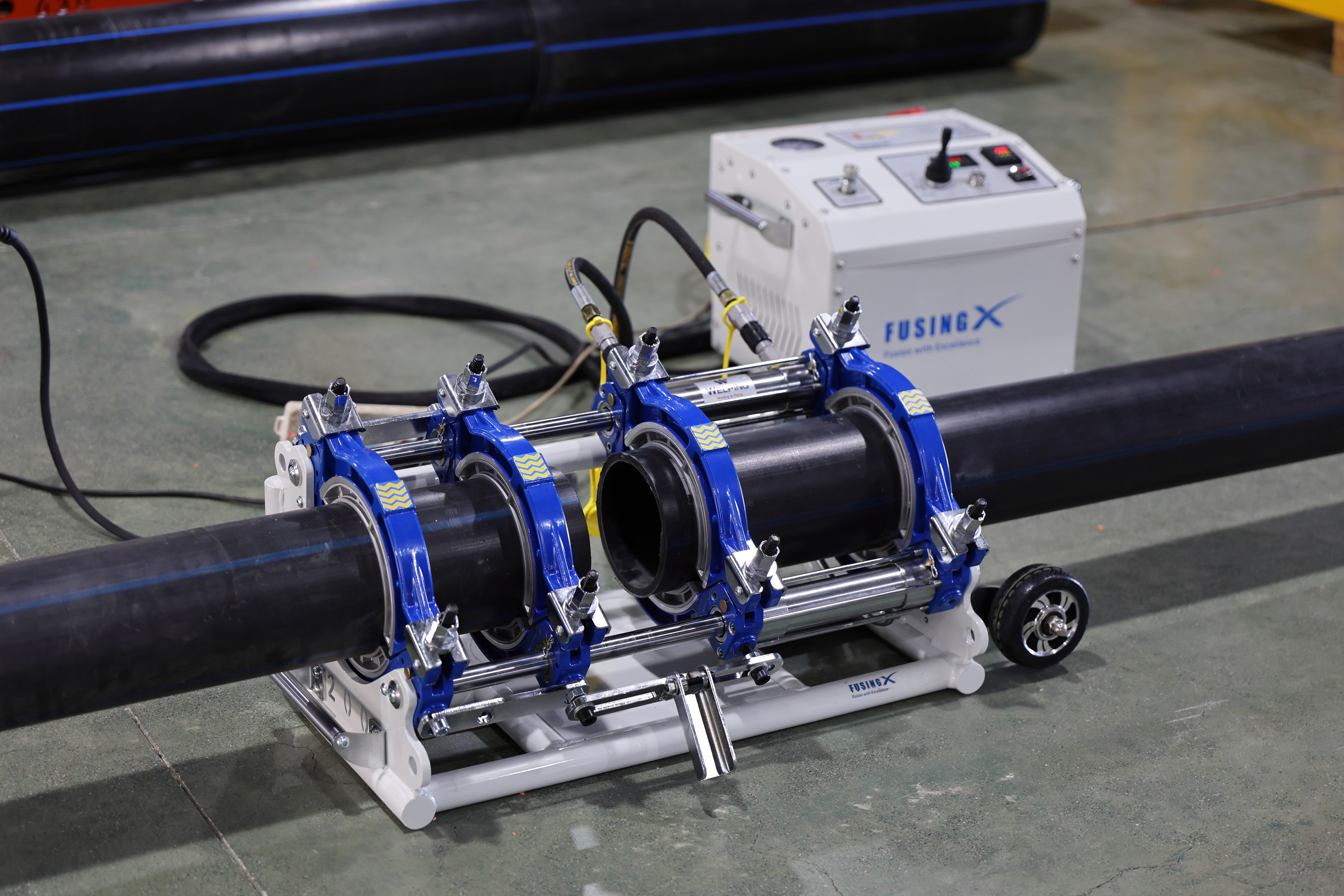

This is where full automation changes the game. New-generation butt fusion machines are turning welding from a high-skill craft into a repeatable, data-driven process.

These systems virtually eliminate human error. The machine controls every critical parameter—heat, pressure, and time—with precision no operator can match. Every single time. They also generate digital reports automatically, creating a certified record for every weld. No more guessing or worrying about missing records.

Most importantly, fully automated welding machines significantly enhance efficiency. With shorter cycle times and near-zero rework, projects move faster and stay on budget. You don’t need a veteran welder to supervise every step; the machine guides the process.

More Than Just a Machine

It’s not just about better hardware—it’s about better workflow. Modern automated welders can connect to cloud platforms, allowing managers to monitor weld quality in real time from anywhere. It’s like giving your project a digital quality control twin.

Investing in the Future

Switching to automation isn’t just buying a new tool—it’s upgrading your entire approach to welding. It means stronger pipelines, fewer headaches, and a clear competitive edge.

Ready to embrace the future of welding? Discover how our automated solutions can transform your projects.