Conquering Large-Diameter Welding Challenges with WP1000A

- Share

- Issue Time

- Sep 13,2025

Summary

Discover the WP1000A HDPE butt fusion welding machine, designed for large-diameter pipes (630–1000mm). With stable hydraulic pressure, reinforced frame, and precise heating, it delivers stronger joints, faster cycles, and reliable performance for municipal, mining, and industrial projects.

Handling large-diameter HDPE pipes is never simple. The bigger the pipe, the greater the pressure, and the harder it is to keep everything aligned. Just one weak weld can lead to leaks, shutdowns, and expensive repairs. That’s why projects of this scale demand a machine built specifically for the job—the WP1000A HDPE butt fusion machine.

The Common Obstacles

Traditional welding setups often face three tough challenges:

· Sustaining stable pressure under heavy loads

· Holding massive pipes in precise alignment

· Achieving uniform heating and cooling on thick pipe walls

How WP1000A Overcomes Them

The WP1000A is engineered to handle these problems head-on:

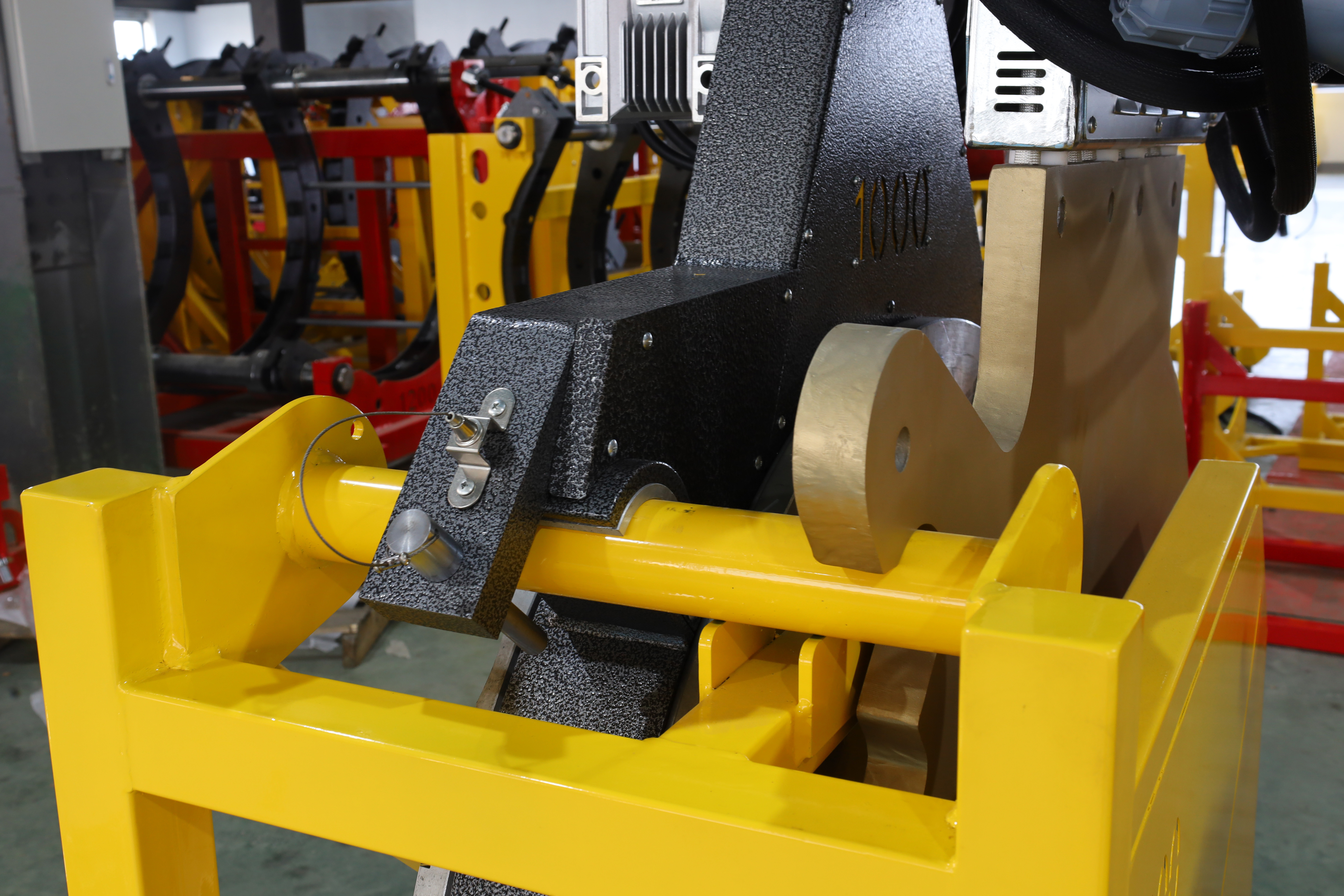

· Robust Hydraulic System – delivers steady, dependable pressure throughout the weld

· Reinforced Frame – ensures large pipes stay aligned and secure

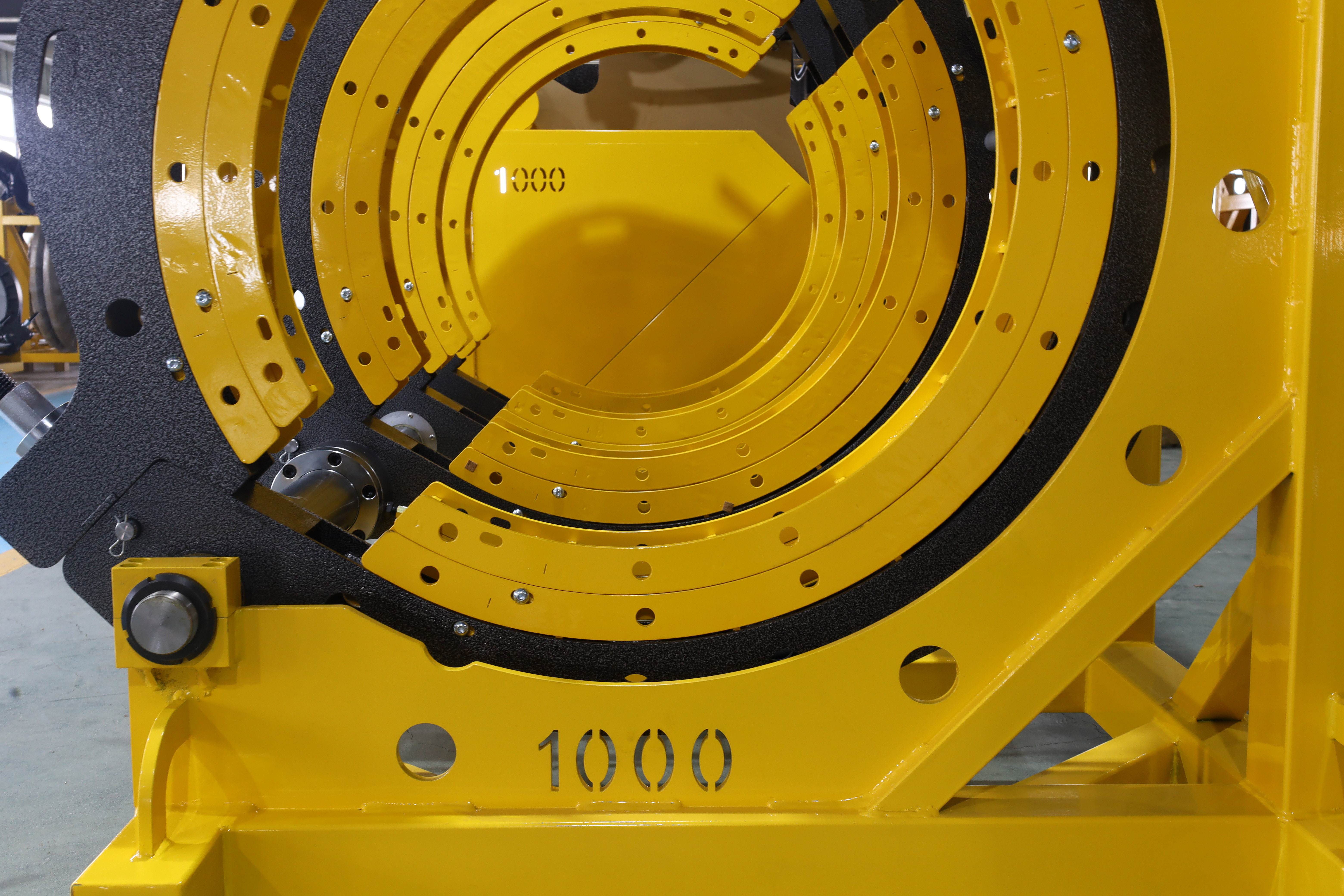

· High-Precision Heating Plate – heats up to 270°C with minimal temperature deviation

· Wide Application Range – standard 800–1000 mm, with optional reducers for 630/710 mm

Built for Demanding Projects

For contractors, the advantages are clear: stronger joints, fewer mistakes, shorter welding cycles, and reduced downtime. From municipal water supply to mining and heavy industry, the WP1000A provides the reliability you need when it matters most.

Ready to upgrade your large-diameter welding projects?Discover the WP1000A today.