The Role of Single-Size Clamp Inserts in Perfect Pipe Alignment

- Share

- Issue Time

- Oct 4,2025

Summary

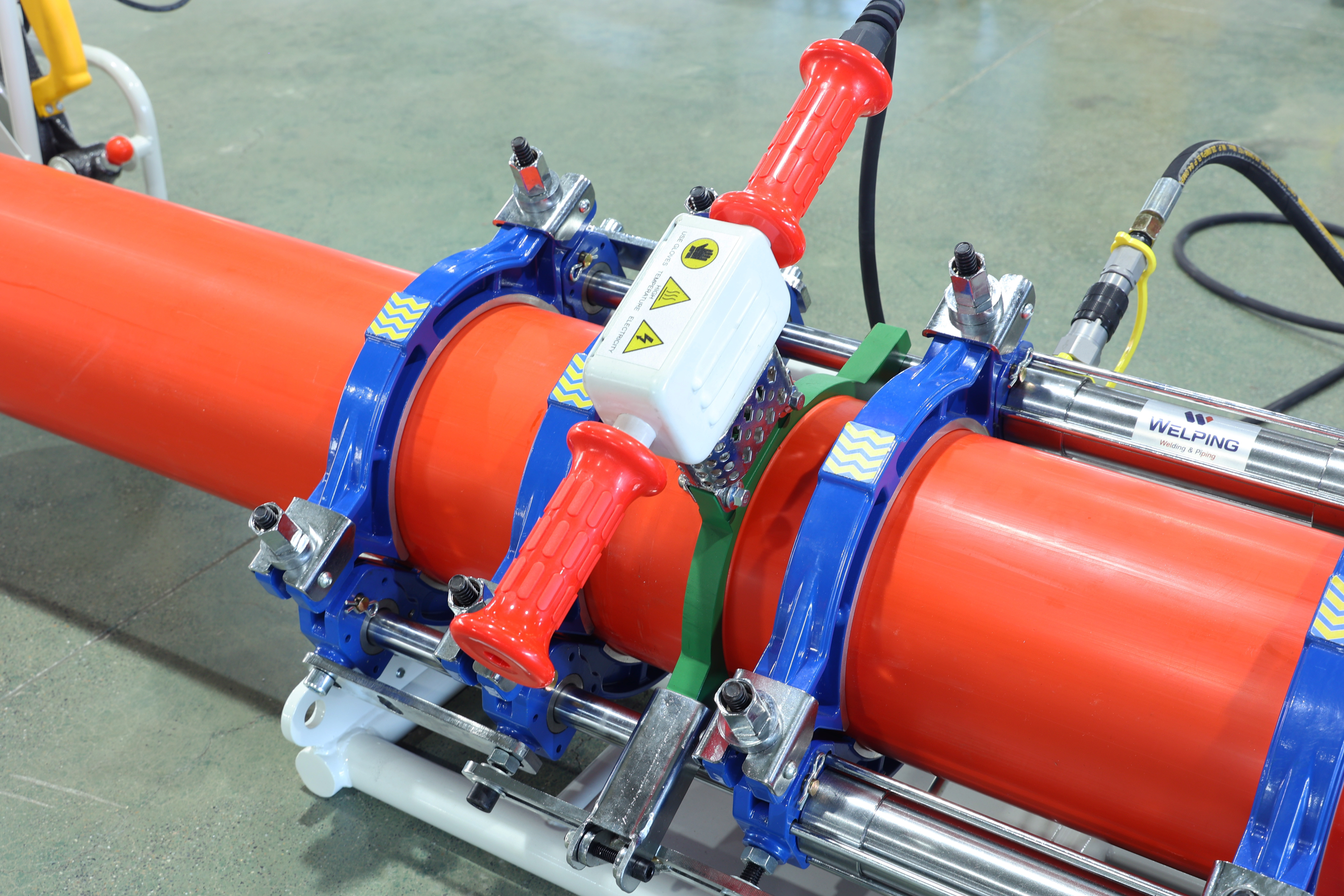

In butt fusion welding, single-size clamp inserts are crucial. They are specialized fittings inside machine clamps that secure pipes of specific diameters, ensuring pipe centering and stability during welding. With advantages like accurate alignment, time-saving, quality improvement and durability, Welping also offers high-quality ones matching its fusion welding machines.

In butt fusion welding, proper pipe alignment is the foundation of a strong joint. Even a small misalignment can create weak spots, leading to leaks or joint failures. This is where single-size clamp inserts make a big difference.

So, what exactly are they? Single-size clamp inserts are specially designed fittings placed inside the machine clamps. They hold pipes of a specific diameter securely, ensuring the pipe stays centered and steady throughout the welding process.

Why do they matter?

· Accurate Alignment – keeps pipes perfectly centered

· Time-Saving – reduces repeated adjustments before welding

· Better Quality – minimizes the risk of misaligned joints

· Durable and Reliable – built for long-term site use

At Welping, we provide high-quality clamp inserts designed to fit our butt fusion machines perfectly. Each insert is carefully engineered to match pipe dimensions, giving operators confidence in every weld.

A strong joint always starts with perfect alignment. With Welping’s single-size clamp inserts, you get the precision and stability needed for reliable welding results.

Learn more about our welding accessories here.