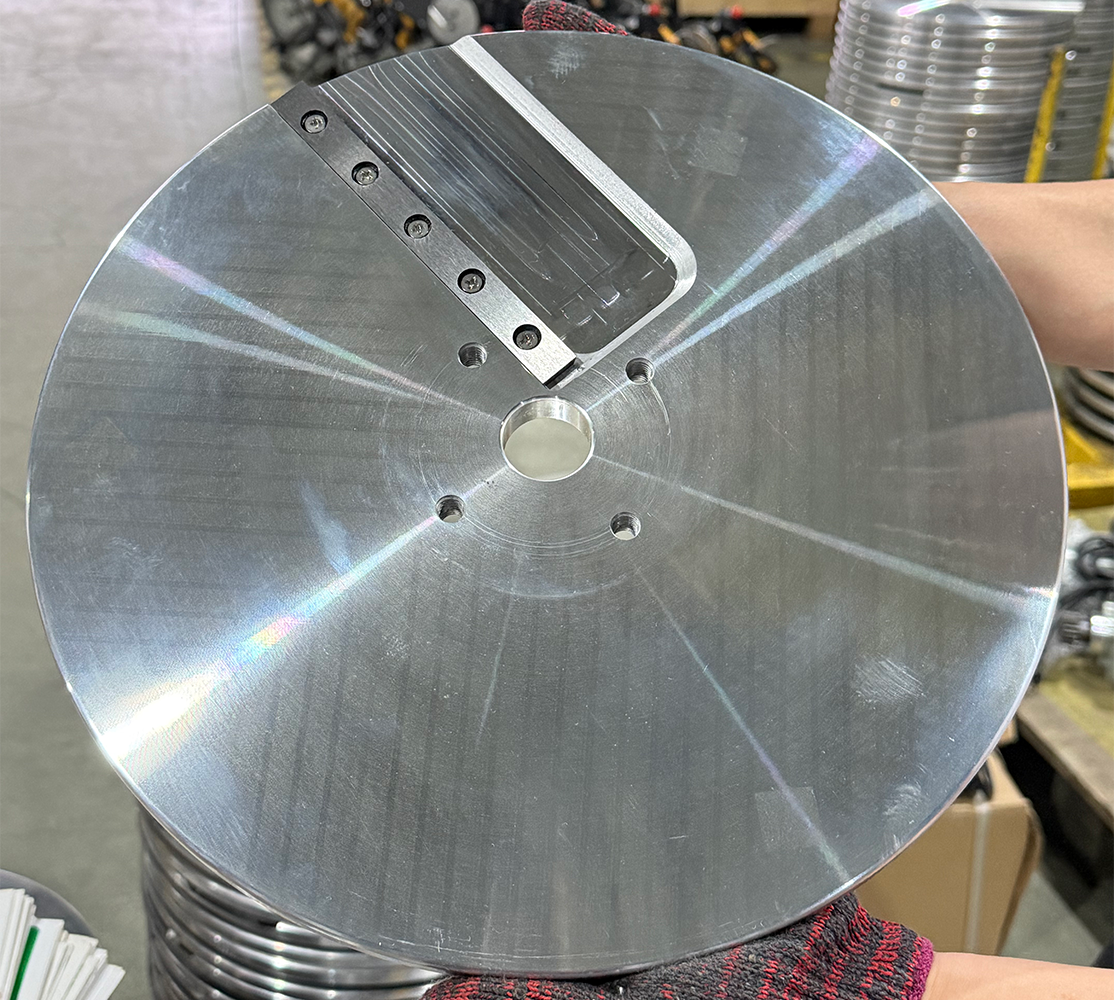

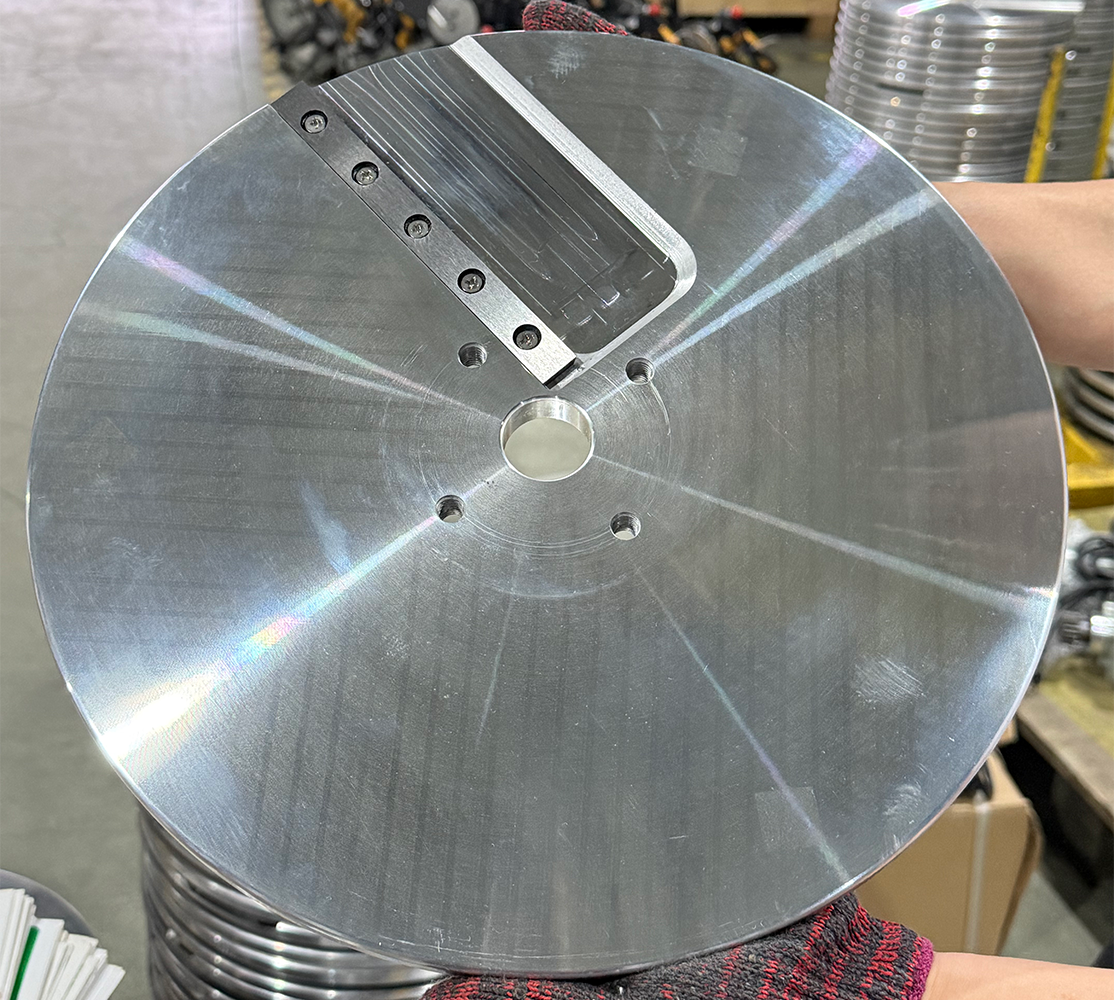

Precision in Every Detail — Manual Facer Blade Inspection Before Assembly

- Share

- publisher

- RUBR

- Issue Time

- Dec 11,2025

Summary

Before assembly, each facer blade undergoes careful manual inspection to confirm surface quality, cutting edge condition, and smooth rotation. This process helps ensure stable cutting performance, clean pipe-end preparation, and reliable operation of butt fusion machines in real field conditions.

Before each facer blade is installed on a butt fusion machine, it goes through a dedicated manual inspection process. This step helps ensure consistent facing performance and long-term reliability in actual field use.

The photos capture technicians in the workshop carefully wiping, inspecting, and selecting each blade prior to assembly.

Key Inspection Focus

Key Inspection Focus

During manual inspection, three core aspects are carefully checked.

Surface Condition

Each blade surface is examined for bubbles, dents, or any visible imperfections that could interfere with smooth and stable cutting.

Cutting Edge Quality

The cutting edge is checked for sharpness, cleanliness, and signs of corrosion. A clean, sharp edge is essential for maintaining proper cutting efficiency and controlled torque during facing.

Rotation and Surface Finish

By manually rotating the blade, technicians confirm smooth movement and consistent surface finishing. This ensures balanced machining quality on both sides of the blade.

Why Manual Inspection Matters

Although the blades are CNC-machined, manual inspection remains an essential step. Certain minor surface or edge details may not be evident through automated processes alone, yet even small imperfections can affect pipe alignment or increase resistance during facing operations.

Supporting Reliable Facing Performance

By verifying surface quality, edge sharpness, and rotational smoothness, the inspection process helps ensure that each facer blade delivers:

· Stable cutting torque

· Clean, even pipe-end surfaces

· Reliable performance during long-term field operation

A Standard Part of Quality Control

Manual wiping and selection are built into the regular production workflow. This routine reflects a consistent approach to quality control and the attention given to every component before it becomes part of a completed butt fusion welding machine.