Evolution of the FusingX Hydraulic Unit

- Share

- publisher

- RUBR

- Issue Time

- Jan 12,2026

Summary

This article looks at the evolution of the FusingX hydraulic unit, comparing the first- and second-generation designs and explaining how the latest version developed through long-term job-site use.Based on continuous field feedback, the second-generation unit introduces improvements in mobility, protection, operating flexibility, and overall usability, making it more suitable for HDPE butt fusion welding and extended on-site operation.

The image above shows a direct comparison between the first-generation and second-generation FusingX hydraulic units.

Both units are used as part of the FusingX butt fusion welding systems under Welping and serve as a key component within the overall welding setup.

The second-generation hydraulic unit was developed based on long-term use in real engineering projects.

Through ongoing on-site operation, several practical limitations of the first-generation unit became apparent. In response, the structure, operating method, and overall layout of the hydraulic unit were gradually refined.

Rather than focusing on a single feature, this update addresses multiple job-site requirements at once, including ease of movement, protection in harsh environments, operating logic, and overall system completeness.

1. Wheels Added as Standard for 400 mm and Larger Models

As hydraulic units designed for 400 mm and larger pipe sizes increase in capacity, their overall weight also increases.

In real construction environments, manually moving heavier equipment adds physical strain and can interrupt workflow.

Based on these conditions, wheels are now included as standard on second-generation FusingX hydraulic units from 400 mm and above, allowing easier positioning and more efficient relocation on site.

2. Flip-Top Structure Better Suited to Job-Site Conditions

Dust and debris are common in HDPE pipe welding environments.

During extended use of the first-generation hydraulic unit, this factor became increasingly noticeable in daily operation.

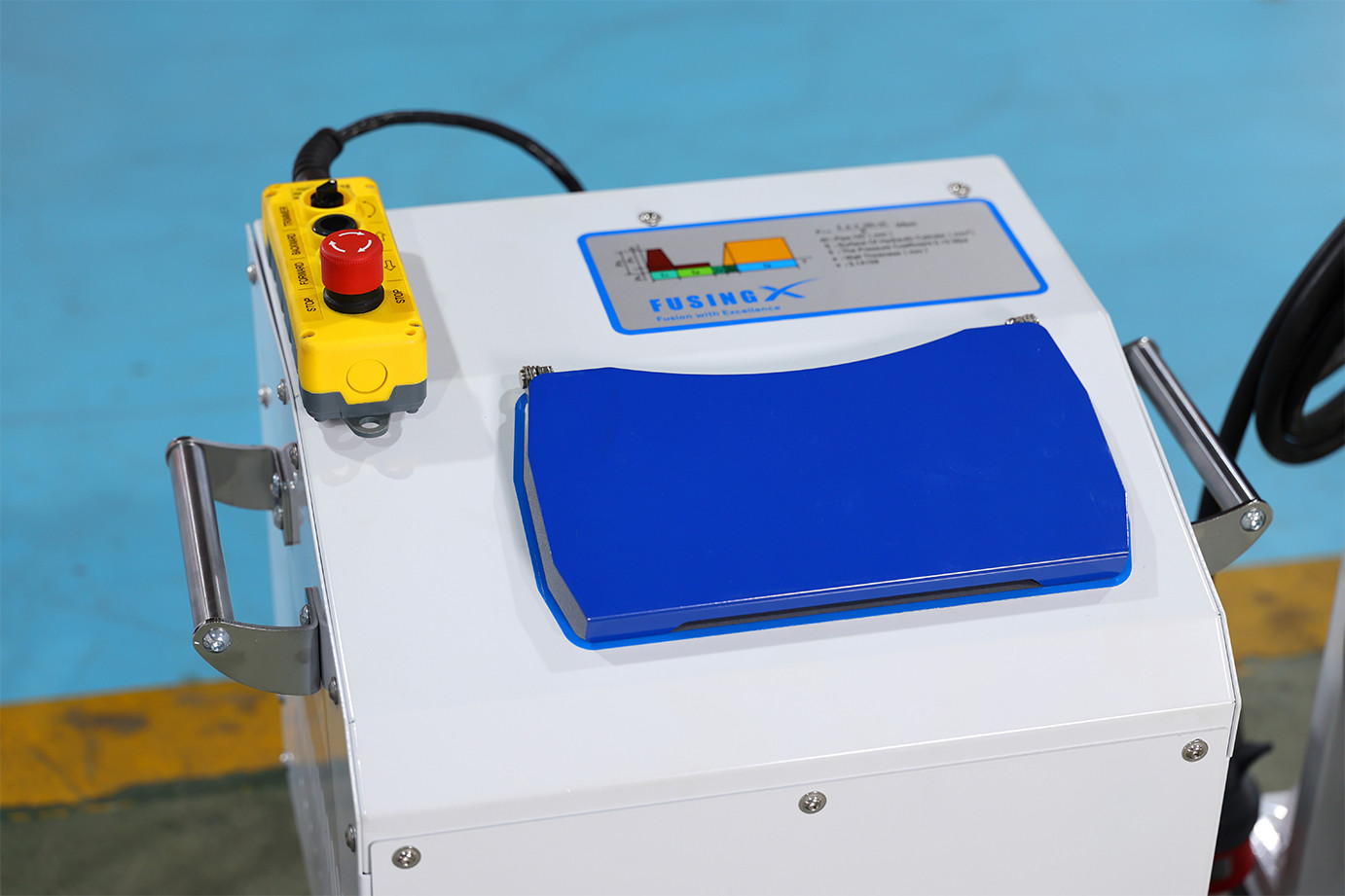

To address this, the second-generation hydraulic unit adopts a flip-top structure. This design helps protect internal components during operation and storage, while also providing more convenient access when inspection or adjustment is required.

3. Remote Control Operation for Greater Flexibility

On the first-generation FusingX hydraulic unit, operation relied mainly on a manual control lever, requiring the operator to remain close to the unit.

In practical butt fusion welding work, operators often need to move around the machine to observe pipe alignment and welding conditions. Returning to the hydraulic unit for every adjustment is not always efficient.

To better match real working habits, the second-generation hydraulic unit introduces remote control operation, allowing operators to move freely while maintaining full control of the welding process.

4. Reorganized Control Panel with Clearer Operating Logic

As shown in the comparison image, the control panel layout of the second-generation hydraulic unit has been reorganized.

Controls and indicators are grouped more logically, the interface is cleaner, and the relationship between functions is easier to understand at a glance.

This adjustment does not reduce functionality, but instead makes operation more intuitive and efficient during on-site work.

5. Unified Structure and Refined Overall Appearance

Alongside functional updates, the second-generation FusingX hydraulic unit features a more unified structure and a refined overall appearance.

The proportions appear more balanced, contributing to visual stability during movement and better alignment with the overall design language of the FusingX welding system.

Summary

The second-generation FusingX hydraulic unit represents a practical evolution shaped by real construction environments and long-term field use.

By improving mobility, protection, operating flexibility, and overall design coherence, it provides stronger support for HDPE butt fusion welding applications and the demands of reliable, long-term on-site work.