Automatic Butt Fusion Welding Machine with Data Logger 200mm

- Model

- WP200Q

Item specifics

- Fusion Capacity

- 200mm Max.

- Lead Time

- 7-15 days once order confirmed

- Package

- Plywood case

Review

Description

INTRODUCTION

DETAILS

WELPING full-auto butt fusion welding machines , are designed to carry out butt fusion operations correctly and efficiently, for plastic pipes, material of PE, PP, PB, PVDF etc.

Suitable for using in applications of municipal drainage, natural gas, sewage, chemical, agricultural irrigation and so on.

Precision die casting aluminum clamps, steel base with cylinder & auto-jump device, provides stable performance Integrated digital control system with LCD display, welding parameters auto setting

Heating plate with high quality PTFE coating, enables swift temperature control.

FEATURES

·Due to the fully enclosed design, the hydraulic station could prevent the operators from being injured.

·A 7" inch, 16-bit true color touch screen has been installed, and buttons are also availabe.

·There are three operational lanuages: English, Russian and Chinese.

·Each operation step is reminded by a flash which can help operators quite understand it.

·All connections sockets are located at the back of hydraulic station, including sockets for planing tool and heating plate. No additional power distributor is needed.

·All welding reports could be saved immediately to internal memory after welding accomplished, or print the report. Meanwhile, it is available for downloading through the USB interface.

·Power supply voltage, frequency, pressure and heating plate temperature are always detected by PLC control unit.

STANDARD ACCESSORIES |

|

|

Main Frame

|

1 Set

|

|

Heating Plate

|

1 Set

|

|

Trimmer

|

1 Set

|

|

Reducers

|

1 Set

|

Tool Box | 1 Set |

PARAMETER

|

Mode

|

WP200Q

|

|

Suitable materials

|

PE,PP, PB. PVDF

|

|

Range

|

63-90-110-160-200mm

|

|

Power supply

|

110V/220V

|

Frequency | 50HZ |

Total power | 3.65KW |

Heating plate | 1.8KW |

Planing tool | 1.1KW |

Hydraulic Unit | 0.75KW |

Max Temperature of Heating plate | 270℃ |

Pressure adjusting range | 0-6.3Mpa,Auto |

Temp.Deviation in Surface | ±5ºC |

Total Weight | 201kg |

Net weight | 181kg |

Packing Size 1 | 124*70*66cm |

Packing Size 2 | 64*47*55cm |

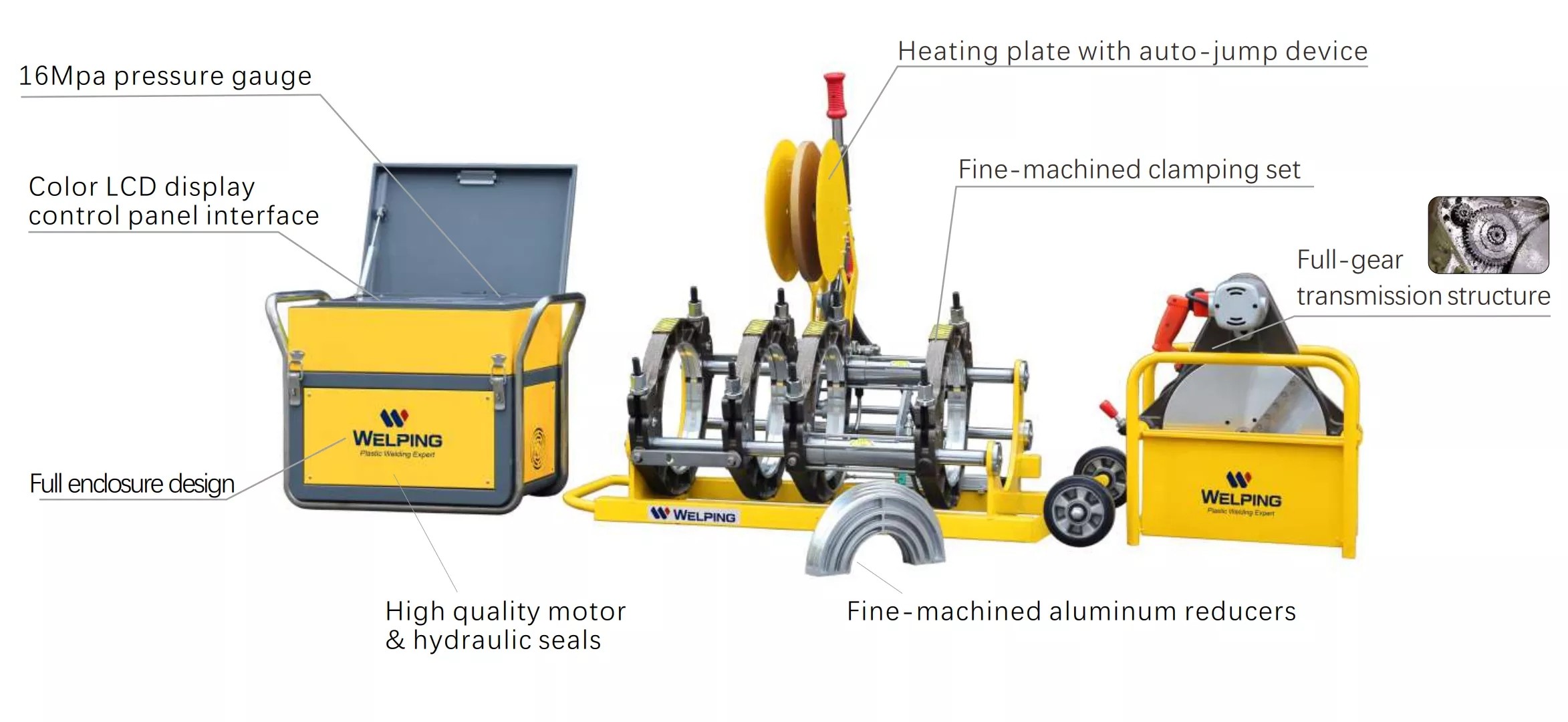

PRODUCT DETAILS MAP

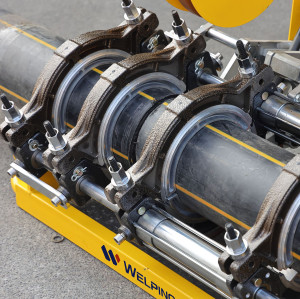

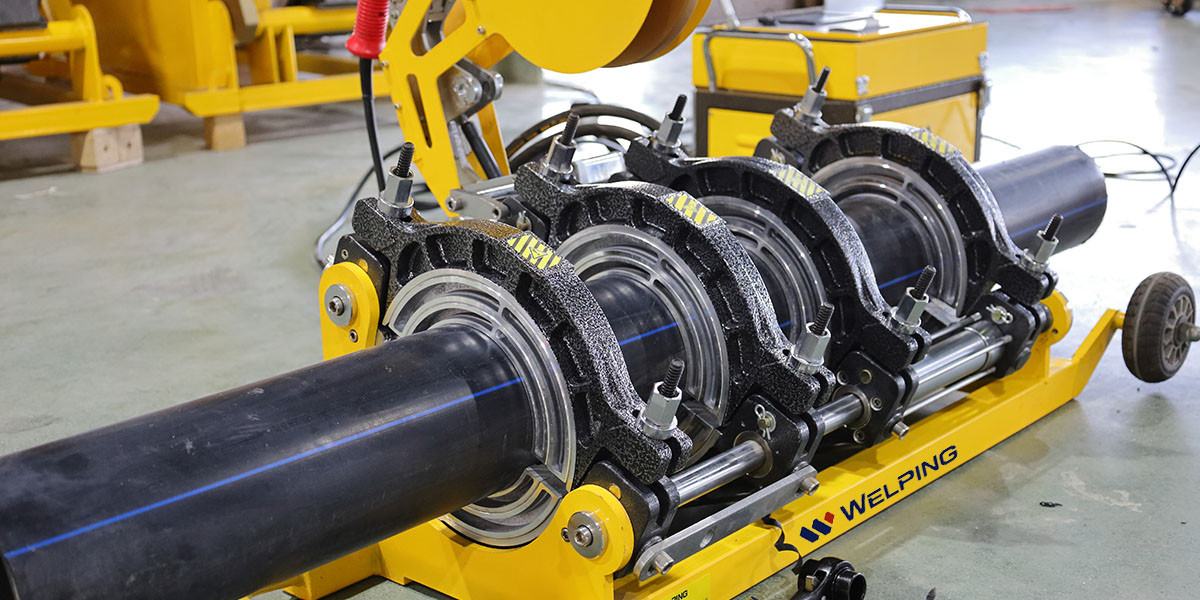

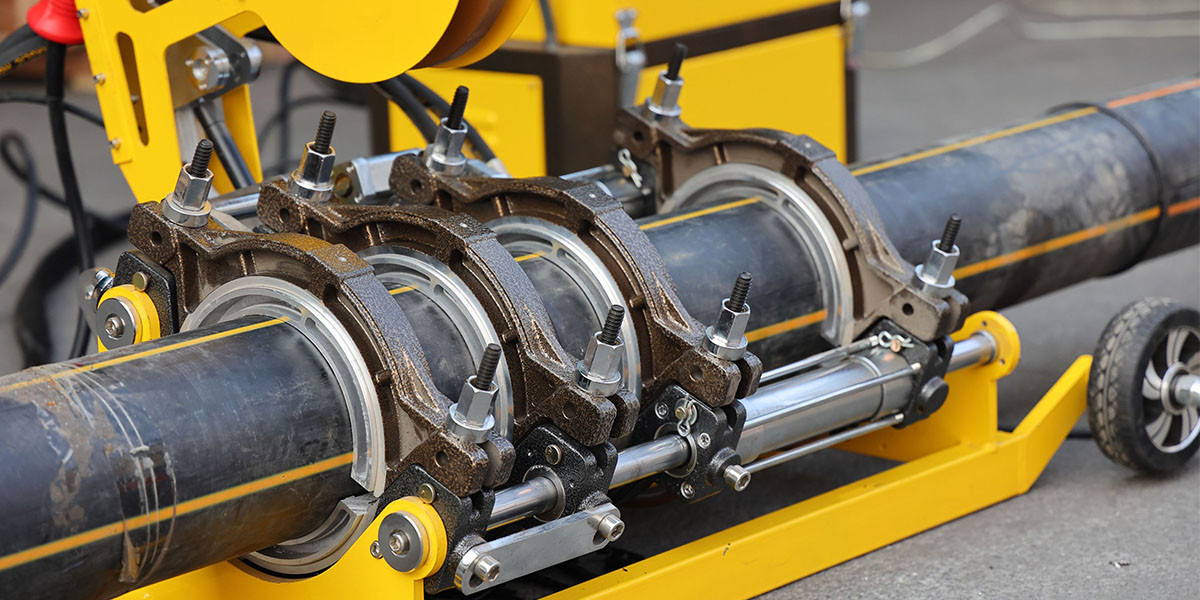

Basic Frame

· 4 Jaw Clamps to ensure precise alignment

· Italy DNP quick coupler

· Chromated hydraulic cylinder made of 1045(ASTM)/S45)(JIS)/C45(DIN) steel

· Chromated integral shaft made of 1045(ASTM)/S45C(JIS)/C45(DIN) steel

· Steel plate cutting clamp with sandblasting &spraying treatment

· Base made of Q235 steel with spraying treatment

Planing Tool

· HSS blade with double edge

· Casting aluminum trimmer plate, durable and anti-corrosion

· Casting aluminum frame of motor with good heat dissipation performance

· Gear transmission

· Motor with pure copper wiring

Hydraulic Unit

· Standard equipping pressure more stable

· Fully enclosure structure shielding splash and dirt

· Electricity leakage protection switch

· 380V asynchronous motor

· Data logger(optional)

· Integrated digital control system with LCD display, welding parameters auto setting

Reducers

63-90-110-160-200mm reducers

DOWNLOAD

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.