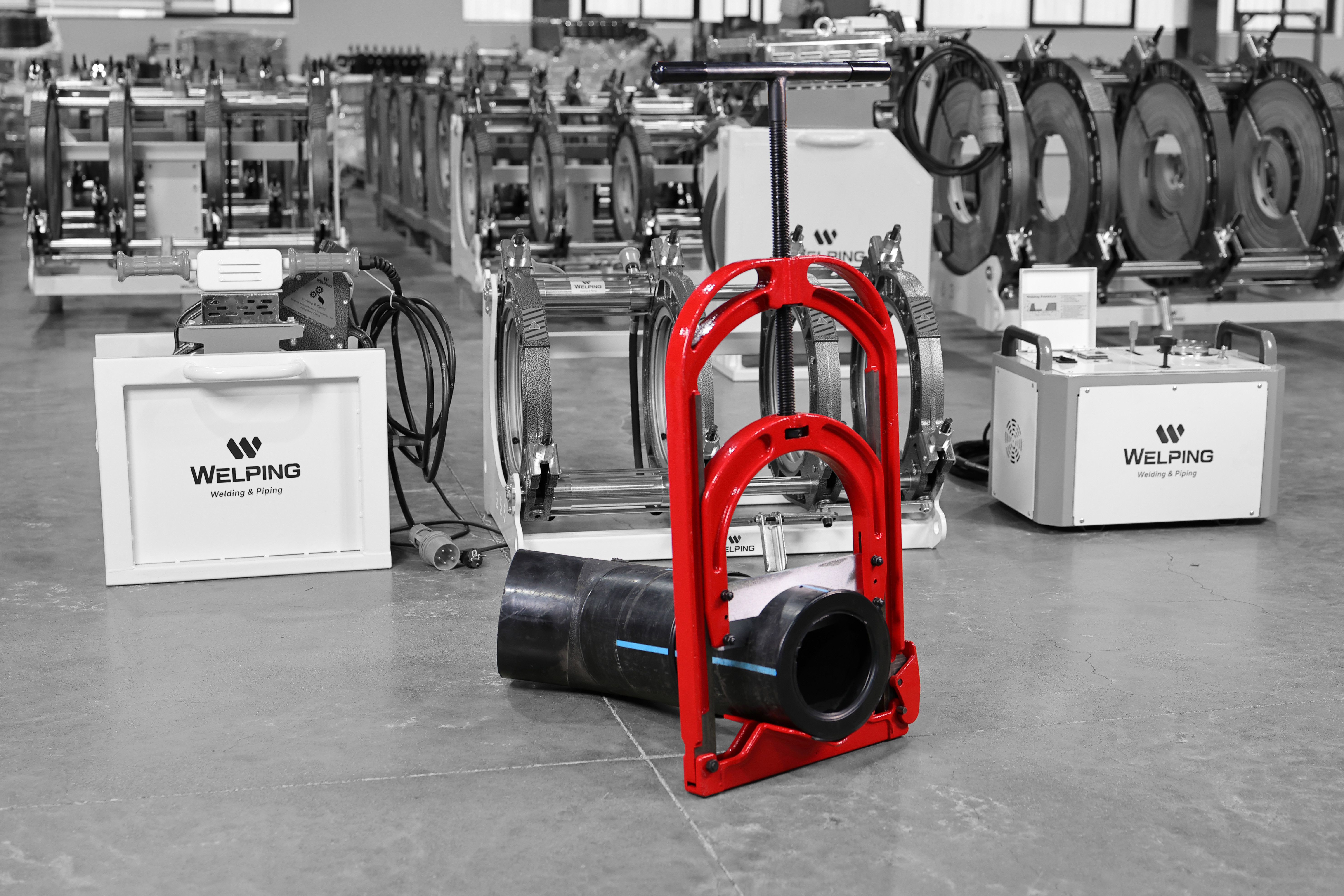

GPC Series HDPE Guillotine Pipe Cutter for PE Pipe in Trench or on Open Ground 50mm-355mm

- Model

- GPC4 / GPC10 / GPC12

Item specifics

- Cutting Range

- 50mm-355mm (3 models)

- Color

- Red (accept customization)

- Pacakge

- 1 set/CTN

- Weight

- 8.5kg/25kg/48kg (3 models)

- Lead Time

- 7-15 days

Review

Description

GPC4/10/12 HDPE GUILLOTINE PIPE CUTTER

DESIGN FEATURES

Feature 1

Suitable for cutting PE pipes both in trenches and on open ground (PVC and PP are not available).

Feature 2

Squarest cut available, within 1/8" (3 mm) on medium and high density pipe, due to strong frames and unique blade design.

Feature 3

Saves facing cost: no facing needed for electrofusion, less needed for butt fusion.

Feature 4

The blade is made of reinforced mold steel, coated with hard chrome, making it super easy to cut without sticking.

Feature 5

GPC10 cuts up to 10" (250mm) instead of traditional 8"(225mm).

Feature 6

GPC12 cuts up to 12" (355 mm).

Feature 7

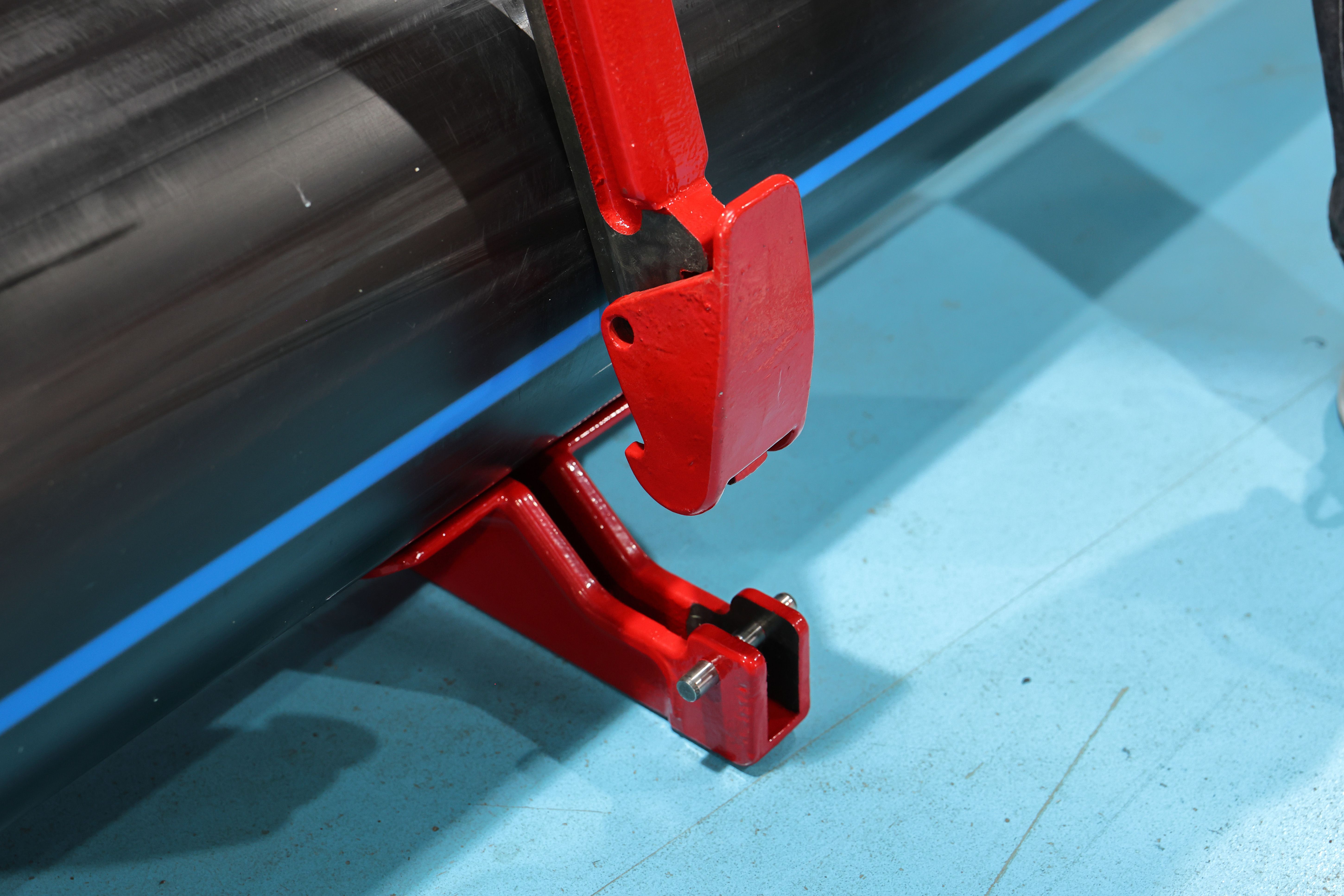

Requires minimal clearance, only 4"-6" (102-152 mm) around pipe.

Feature 8

Clean and safe! No chips to clog valves and apertures.

SPECIFICATION

Item No. | Model No. | Cutting Range | SDR |

740010 | GPC4 | 50 - 125mm (1½" - 4") | SDR15.5 - SDR9 |

740020 | GPC10 | 90 - 250mm (3" - 10") | SDR15.5 - SDR9 |

740030 | GPC12 | 110 - 355mm (4" - 12") | SDR17 - SDR9.3 |

PRODUCT DETAILS

I

Friendly used for reparing GAS and WATER pipe in the trench, together with Butt Fusion Machine.

II

Easy to install on the pipe, and requires minimal clearance 4"-6" (102-152 mm) around pipe.

III

Cutting blade is made of reinforced mold steel, coated with hard chrome. Smooth cutting without sticking.

IV

Squarest cut available on medium and high density pipe, due to strong frames and unique blade design.

WELCOME TO DOWNLOAD

WHY CHOOSE WELPING

Due to its crosshead and blade design, GPC Guillotine Cutter can provide a straight cut with minimal blade wear. And its cutting efficiency is very high. Safe to use than saws because no PE chip residue remains in the pipe that may later clog valves. Especially in special environments, cutting gas pipes can effectively reduce the possibility of combustion and explosion.

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.