Hydraulic Operated HDPE Butt Fusion Welding Machine1200/1600mm Fully

- Model

- WP1600AH

Item specifics

- Lead Time

- 7-15 days once order confirmed

- Terms of Payment

- T/T, Western Union, Paypal,X Transfer

- FOB Port

- Shanghai, Ningbo

- Certificate

- CE

- MOQ

- 1 Set

- Business type

- Plastic pipe welding machines manufacturer

Review

Description

1200/1600mm Hydraulic Butt Fusion Welding Machine for PE Pipes

DETAILS

HDPE pipe has been used extensively in the piping applications of municipal, industrial, marine, mining, landfill, duct and agricultural industries.

Butt fusion welding is an effective, trouble free connecting method for PE, HDPE pipes. In pressurized piping applications, butt fusion welding machine can provide reliable joints, even as strong as the complete pipe.

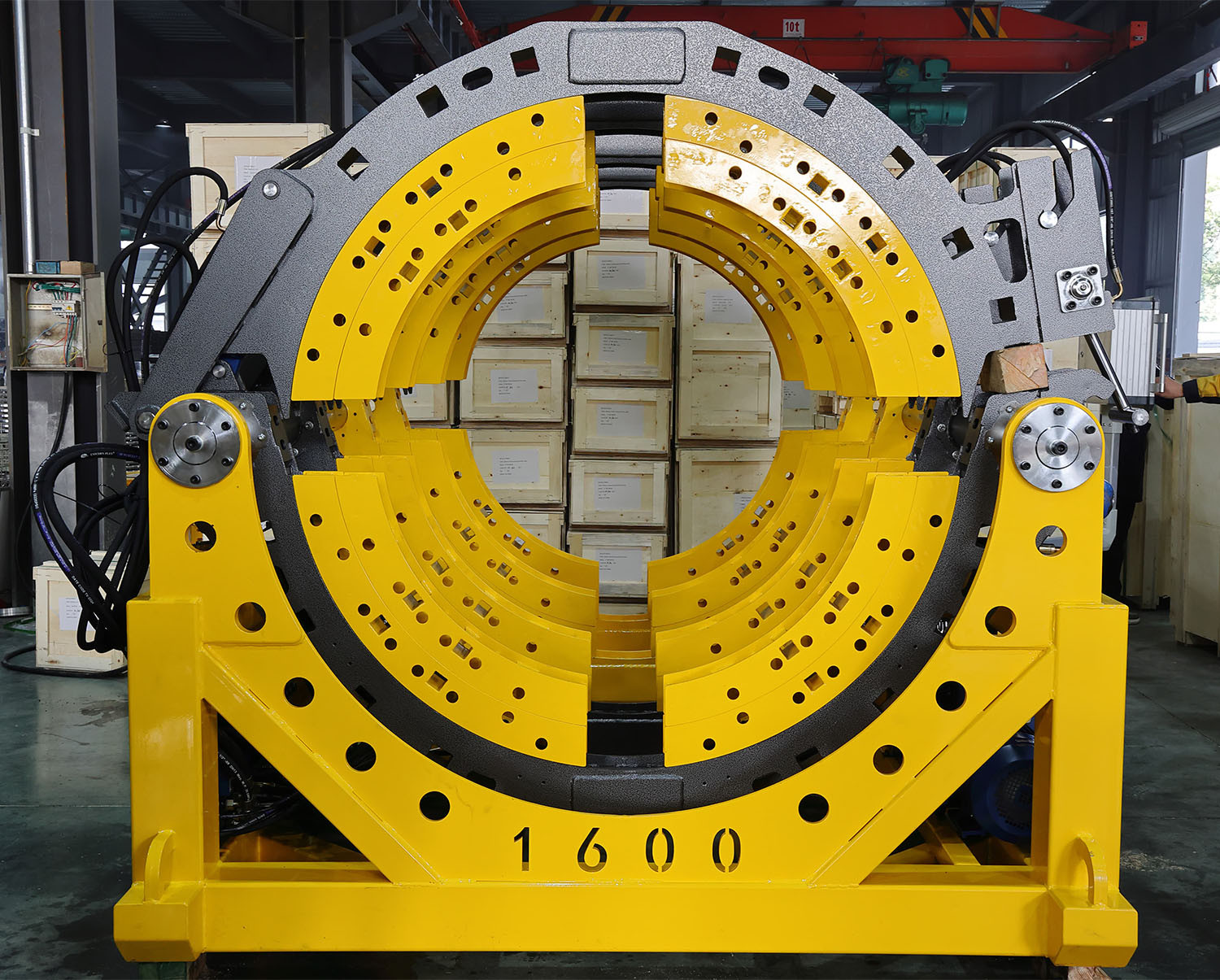

The 1600mm butt welding machine is a mechanical butt fusion welder for joining various types of plastic pipe including HDPE,PP,PB and PVDF.

The 1600mm fully hydraulic butt welding machine features hydraulic locking and loosing,opening and closing mechanisms. With its advanced hydraulic system, this welding machine provides precise and efficient welding results.

The hydraulic butt fusion machine allow for easy access to the welding area, making it easier to set up and maintain the machine. The opening and closing mechanisms are also fully hydraulic, providing smooth and safe operation.

The machine is designed to handle large diameter pipes and provides a stable and reliable welding process. Its advanced features make it an ideal choice for welding large diameter pipes in various industries.

STANDARD ACCESSORIES |

|

|

Main Frame

|

1 Set

|

|

Heating Plate

|

1 Set

|

|

Trimmer

|

1 Set

|

|

Reducers

|

1 Set

|

Tool Box | 1 Set |

PARAMETER

|

Mode

|

WP1600AH

|

|

Suitable materials

|

PE,PP, PB. PVDF

|

|

Range

|

1200-1400-1600mm

|

|

Power supply

|

380V

|

Frequency | 50HZ |

Pressure adjusting range | 0-25Mpa |

Total power | 61.5 KW |

Heating plate | 50 KW |

Planing tool | 7.5 KW |

Hydraulic Unit | 4 KW |

Max Temperature of Heating plate | 270℃ |

Temp.Deviation in Surface | ±5ºC |

Total Weight | 5200kg |

Packing Volume | 21CBM |

PRODUCT DETAILS MAP

Basic Frame

The 1600mm fully hydraulic butt welding machine is completely hydraulic, meaning that it uses hydraulic pressure to clamp and weld the pipes. This machine has a welding pressure of up to 1600mm, which makes it ideal for welding large diameter pipes.

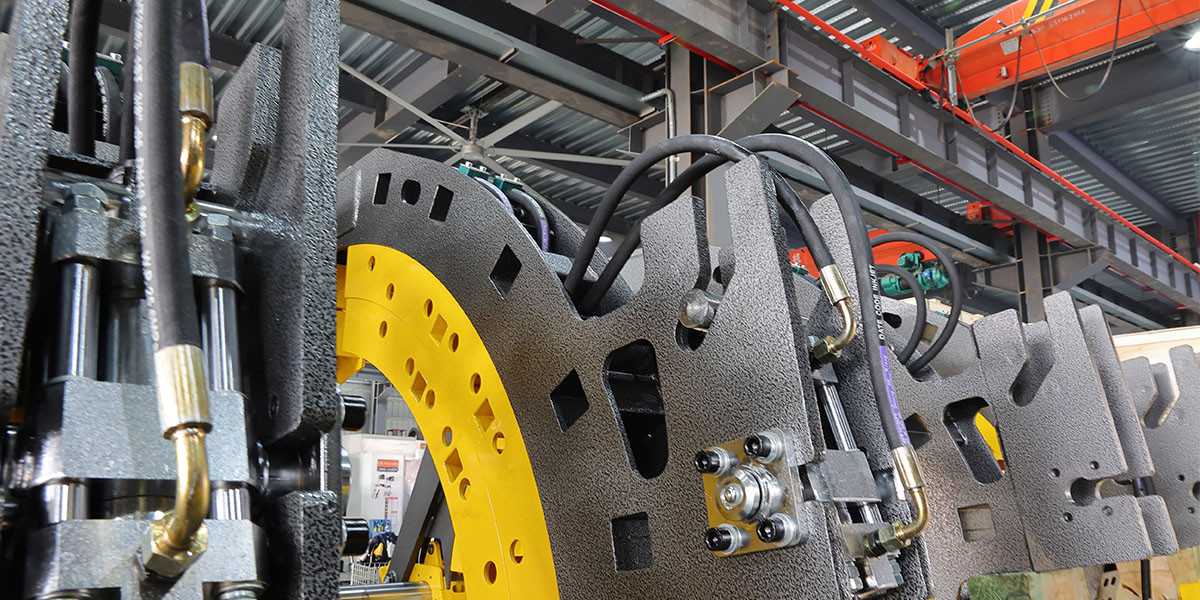

Open/close; lock/loose mechanisms

The machine is designed with safety in mind, with features such as an emergency stop button and safety guards to prevent accidents. The HDPE welder can control the clamps for open/close,and lock/loose.

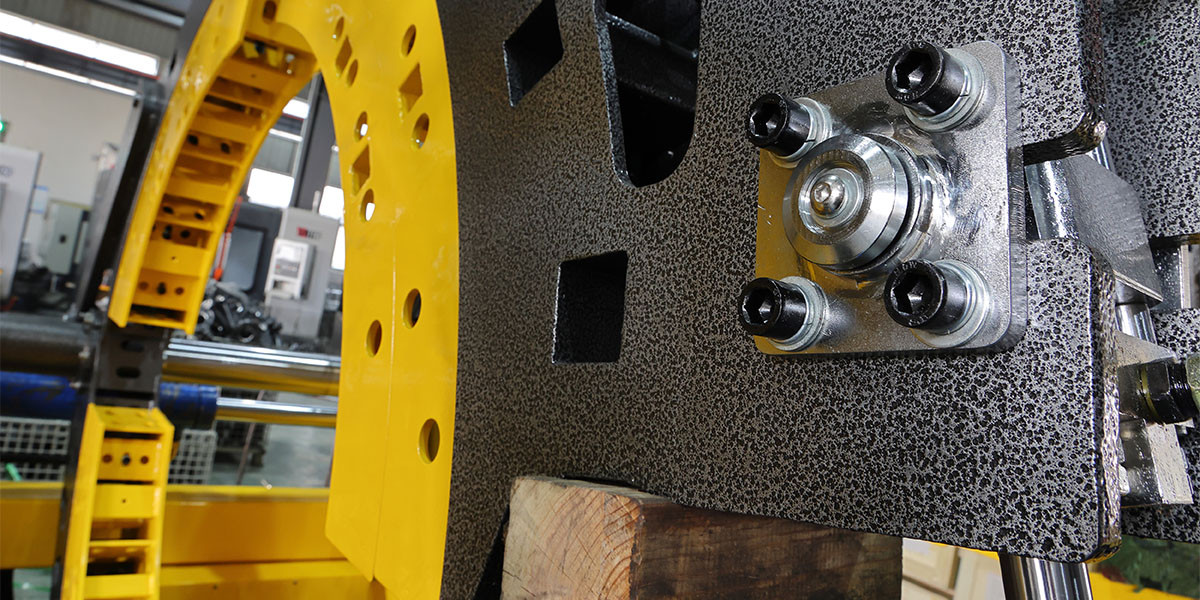

Planning tool

The machine is made from high-quality materials, which makes it durable and long-lasting.

Controller

The machine is easy to operate, as it has a user-friendly control panel and simple controls.

Easy to operate

DOWNLOAD

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.