Compact Hydraulic Roll Groover for Steel Pipe SCH10/SCH40 2"-8 "(RG-3)

- Model

- RG-3

Item specifics

- Grooving Capacity

- 2"-8"

- Max Wall Thickness

- 6mm

- Power Supply

- 800W

- Output Speed

- 30RPM

Review

Description

2"-8" light electric hydraulic groove rolling machine

The RG-3 electric hydraulic grooving machine is suitable for rolling grooves on 2"-8" (DN50~DN200) SCH10/SCH40 steel pipes and stainless steel .

Suitable for a variety of daily tasks involving fire protection pipes, this rolling groover is an integrated tool that includes a motor, hydraulic feed pump, foot switch and pipe rack.

The motor's built-in high-performance gear reduction system allows for a compact design and reduced noise levels.

The unique combination of hydraulic feed pump and trough depth locking knob guarantees a quality trough and optimal efficiency.

scope

|

model

|

RG-3

|

|

Applicable materials

|

Carbon steel, stainless steel

|

capacity |

Suitable for 2"-4" steel pipe SCH10/SCH40 |

Suitable for 5"-8" steel pipe SCH10/SCH20 | |

|

power supply

|

220V/110V

|

frequency | 50Hz/60Hz |

Maximum wall thickness | 6mm |

Motor Power | 800W |

Output speed | 30 rpm |

Packaging gross weight | 47kg |

Package Size | 56*26*65cm |

Ordering Information

|

catalog number

|

stage

|

strength

|

Voltage frequency

|

|

900030

|

single

|

800W

|

220V, 50/60HZ

|

|

900031

|

single

|

800W

|

110V, 50/60HZ

|

Standard Parts

|

Item Number

|

describe

|

net weight

|

|

|

911074

|

Driving roller 2"-6" (φ60~φ168)

|

1.30kg

|

|

|

911075

|

Drive roller 8" (219)

|

1.40 kg

|

|

912018 | Grooved roller 2"-6"(φ60-φ168) | 0.45kg | |

912032 | Grooved roller 8"(φ219) | 0.45kg | |

998028 | 2"-8" pipe rack | 2.20kg | |

Optional accessories

|

Item Number

|

describe

|

net weight

|

|

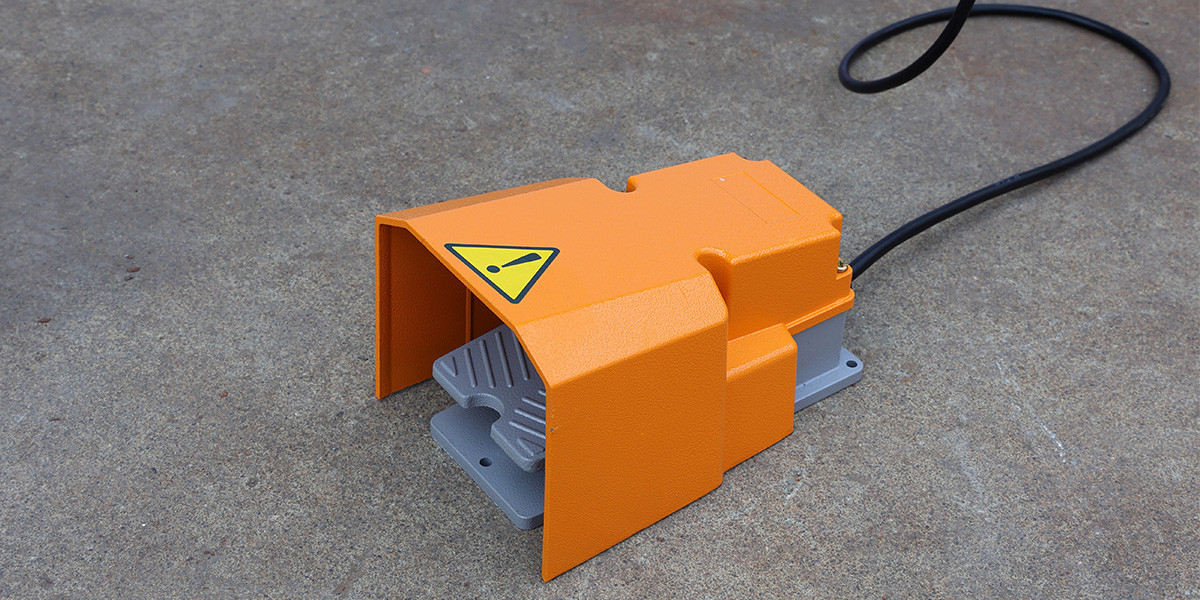

998026 | Foot switch | 1.50kg | |

Product details picture

Pipe rack

Suitable for 2"-8" steel pipe

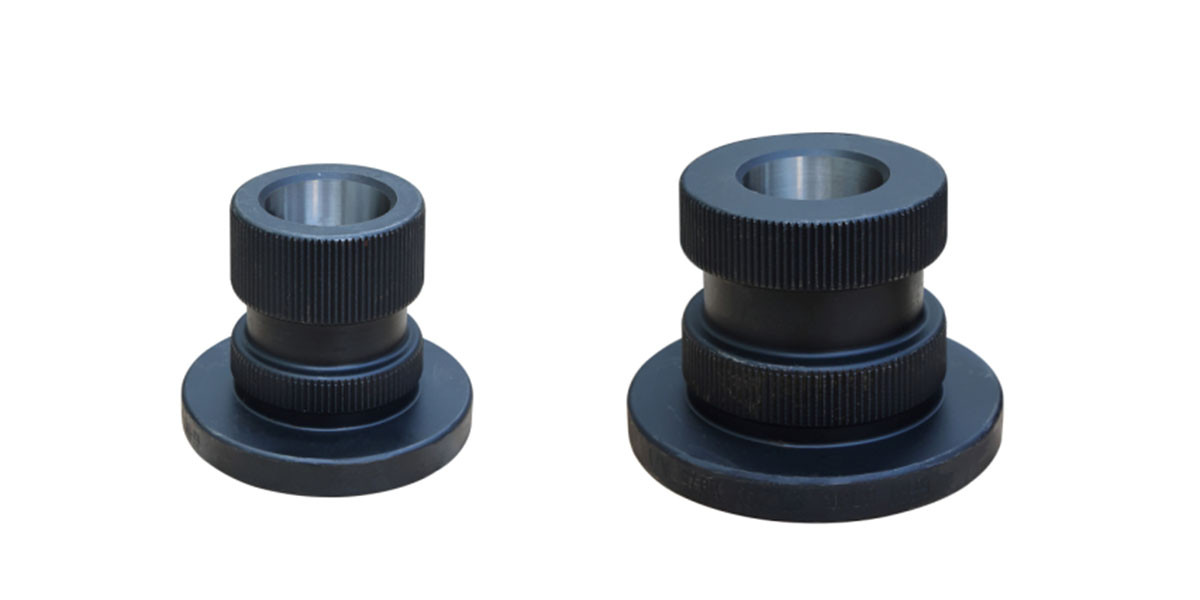

drive roller

A set of 2"-6" (φ60~φ168) ;

Set of 8 " (φ219) ;

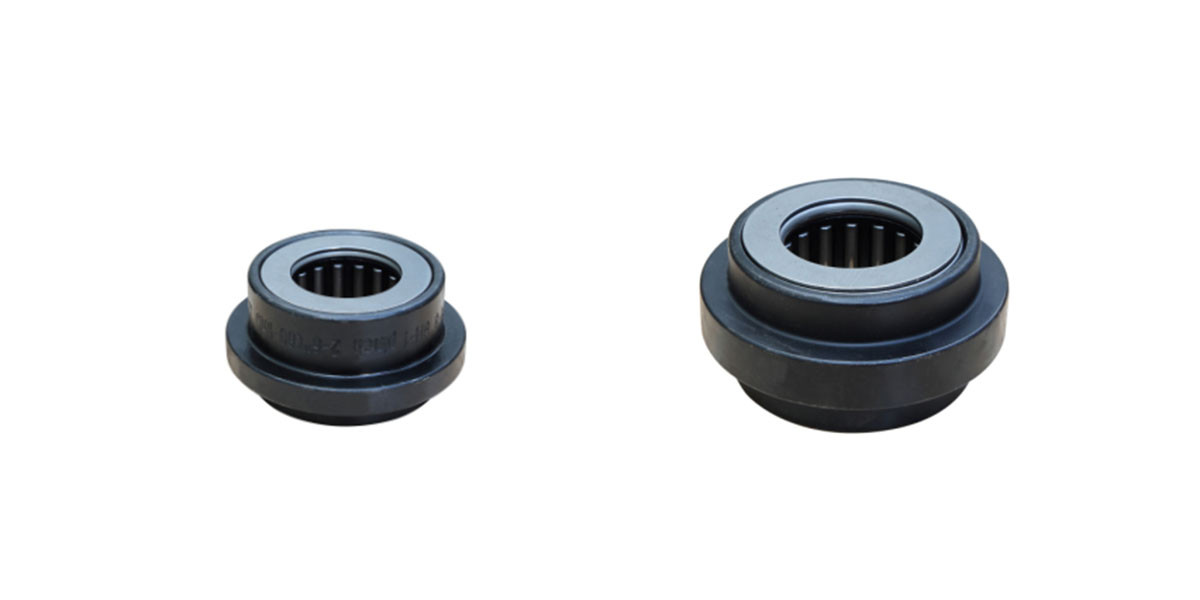

Troughed roller

A set of 2"-6" (φ60~φ168) ;

Set of 8 " (φ219) ;

Foot switch

download

What can we do for you?

our service

WELPING develops, manufactures and sells equipment and systems for welding thermoplastics, consciously focusing on pipe systems as its main application area in this area. Since 2005, we have been in this field for more than 17 years.

Our goal is to help build your reputation by combining industrial-grade design, performance and quality to provide specialized solutions for a variety of mining and industrial, marine, municipal, irrigation, energy and landfill sites.

WELPING strives to be a provider of all things thermoplastic piping, including welding equipment and certified technical training to assist with the installation and fabrication of any plastic piping related project. WELPING continues to expand the supply and use of polyethylene pipe, valve and fitting system designs into new market segments. In addition, we help customers purchase plumbing tools to support their projects. Our success lies in the quality of our products and the knowledge and service of our employees.