High-End Series Hydraulic HDPE Pipe Fusion Welding Machine Wp250A PRO

- Model

- WP250A Pro

Item specifics

- Lead Time

- 7-15 days once order confirmed

- Terms of Payment

- T/T, Western Union, Paypal,X Transfer

- FOB Port

- Shanghai, Ningbo

- Certificate

- CE

- MOQ

- 1 Set

- Business type

- Plastic pipe welding machines manufacturer

Review

Description

High-End Series Hydraulic HDPE Pipe Fusion Welding Machine Wp250A PRO

DETAILS

HDPE pipe has been used extensively in the piping applications of municipal, industrial, marine, mining, landfill, duct and agricultural industries.

Butt fusion welding is an effective, trouble free connecting method for PE, HDPE pipes. In pressurized piping applications, butt fusion welding machine can provide reliable joints, even as strong as the complete pipe.

The High-End Series WP250A PRO butt welding machine is a mechanical butt fusion welder for joining various types of plastic pipe including HDPE,PP,PB and PVDF.

Basic Info

The Butt Fusion Machine is designed to butt fuse pipe sizes 90mm to 250mm. It is easy to operate and incorporates a state-of-the-art heating plate, 4 jaws machine body, electric facer, and storage stand.

| Model NO. | WP250A Pro | Control | Semi-Automatic |

| Frequency Range | Low Frequency | Electric Current | AC |

| Type | Resistance Butt Welder | ODM/OEM | Alternative |

| Package | 2 PCS | Hydraulic | Enclosure Housing |

Certificate | CE, SGS | Warranty | 1 Year |

Heating Plate | 2.3kw | Planing Tool | 2.0kw |

Hydraulic Unit | 0.75kw | Color | White |

Transport Package | Plywood Case | Specification | Hydraulic drive |

Trademark | WELPING | Origin | China |

HS Code | 8515809090 | Production Capacity | 20000pieces/Year |

PARAMETER

| Model | WP250A Pro |

| Welding range | 90-110-125-140-160-180-200-225-250 mm |

| Weldable Material | PE(HDPE, MDPE, LDPE), PP, PVDF, MPP |

| Power supply | 220V, 50/60Hz, 1PH |

| Overall Power | 5.05kW |

Heater | 2.3kW |

Trimmer | 2.0kW |

Hydraulic station | 0.75kW |

Pressure range | 0-8Mpa |

Max. temperature | 270ºC |

Heating plate surface temp | 170-250ºC |

Temperature deviation | ±7ºC |

Gross Weight | 151kg |

Total Volume | 0.5cbm |

PRODUCT DETAILS MAP

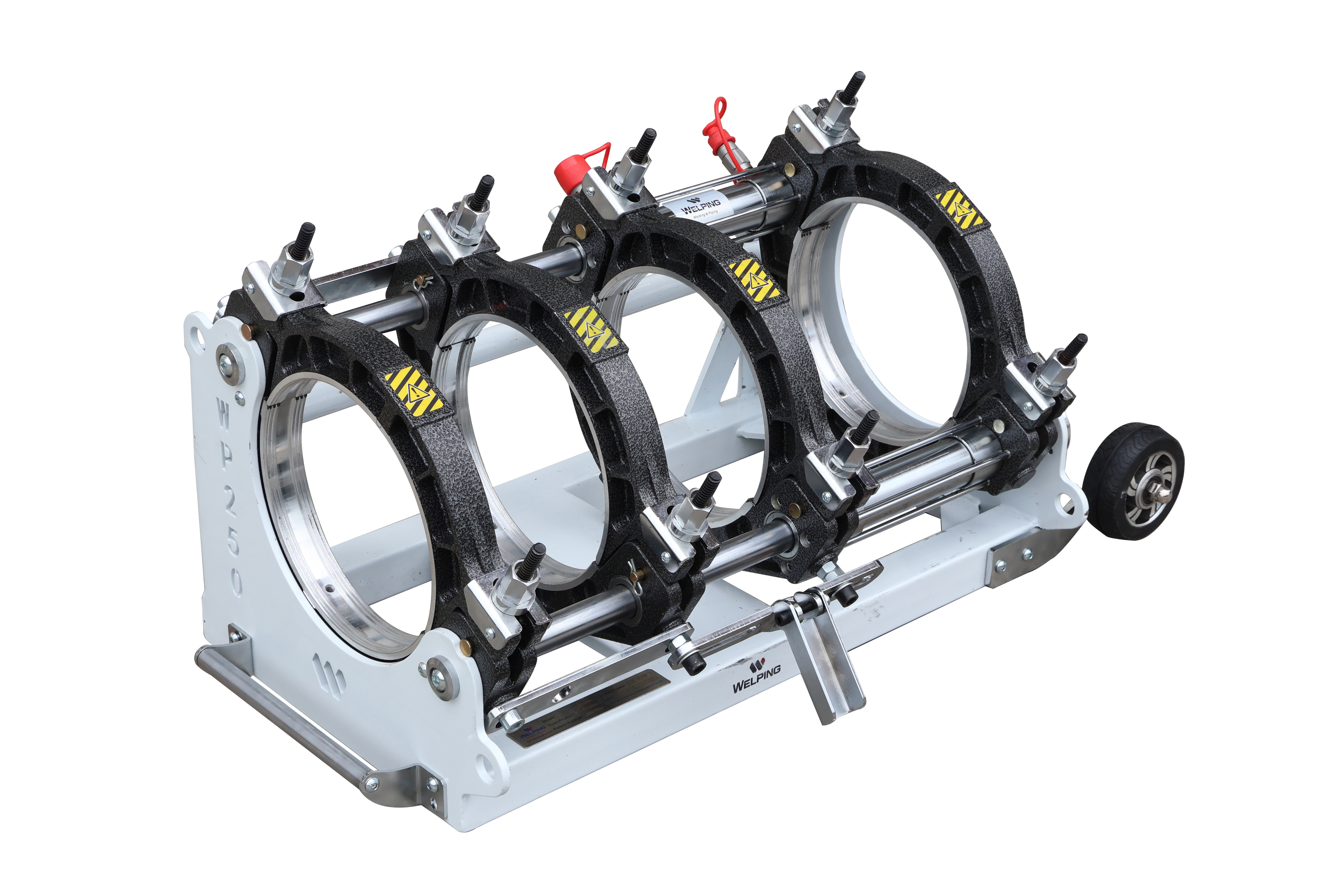

Frame(Carriage)

· Complete steel welded design, with complex reinforced structure, heavy-duty

· Clamping part, inner fine-machined

· Standard equipped with carrying handles and wheels,for easy transportation

· Qualified hydraulic cylinder with quick couplings, for easy installation

Hydraulic station

· Integrated hydraulic and electrical control, for easy operation access

· All-in-one control panel:

hydraulic actuation, pressure setting, timing, electric info display, temperature setting

· Enclosure design, shielding splash and dirt

· Qualified Siemens electrical parts

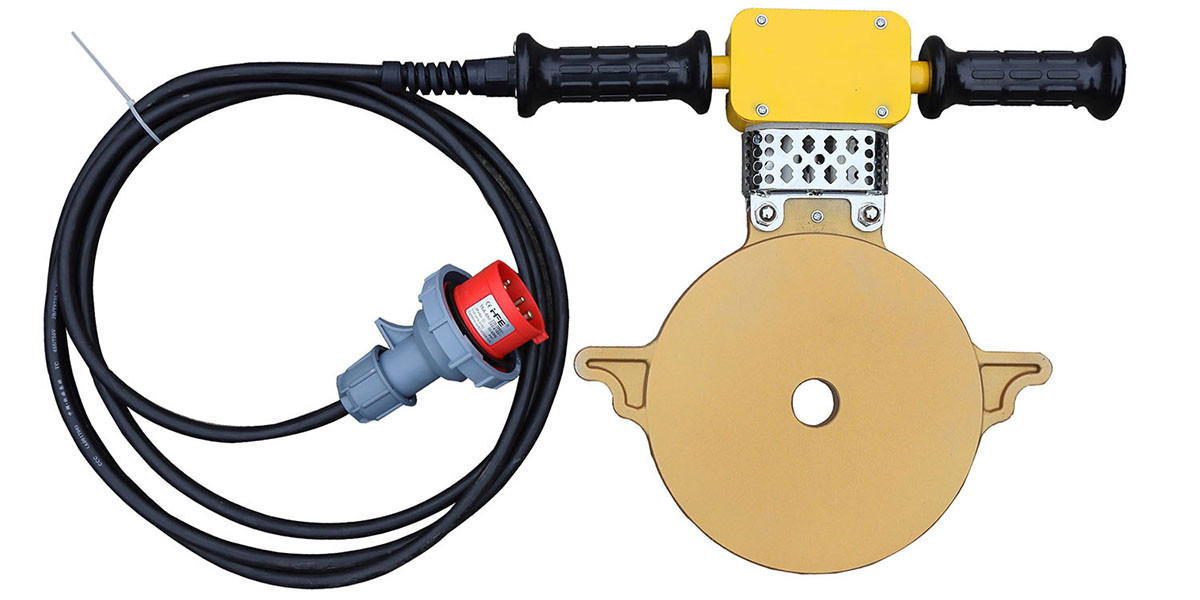

Heating plate

· Cast aluminum body with built-in heating elements

· Anti-stick PEFT coating from Daikin

· Qualified aviation plug and heavy duty cable ensure operation safety

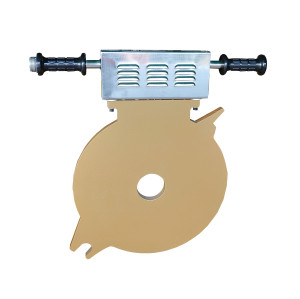

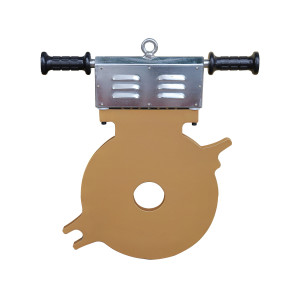

Planing tool (trimmer)

· Full gear transmission structure,for steady and long-life performance

· Powerful copper-wiring motor

· Durable, double edges HSS blades

Tool holder

· Complete heating plate covers for better protection and heating conservation

· Wider and longer handles for better mobility

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.