Manual HDPE Pipe Jointing Machine for 63MM to 160MM Pipes

- Model

- WP160D

Item specifics

- Lead Time

- 7-15 days once order confirmed

- Terms of Payment

- T/T, Western Union, Paypal,X Transfer

- FOB Port

- Shanghai, Ningbo

- Certificate

- CE

- MOQ

- 1 Set

- Business type

- Plastic pipe welding machines manufacturer

Review

Description

Manual HDPE Pipe Jointing Machine for 63MM to 160MM Pipes

DETAILS

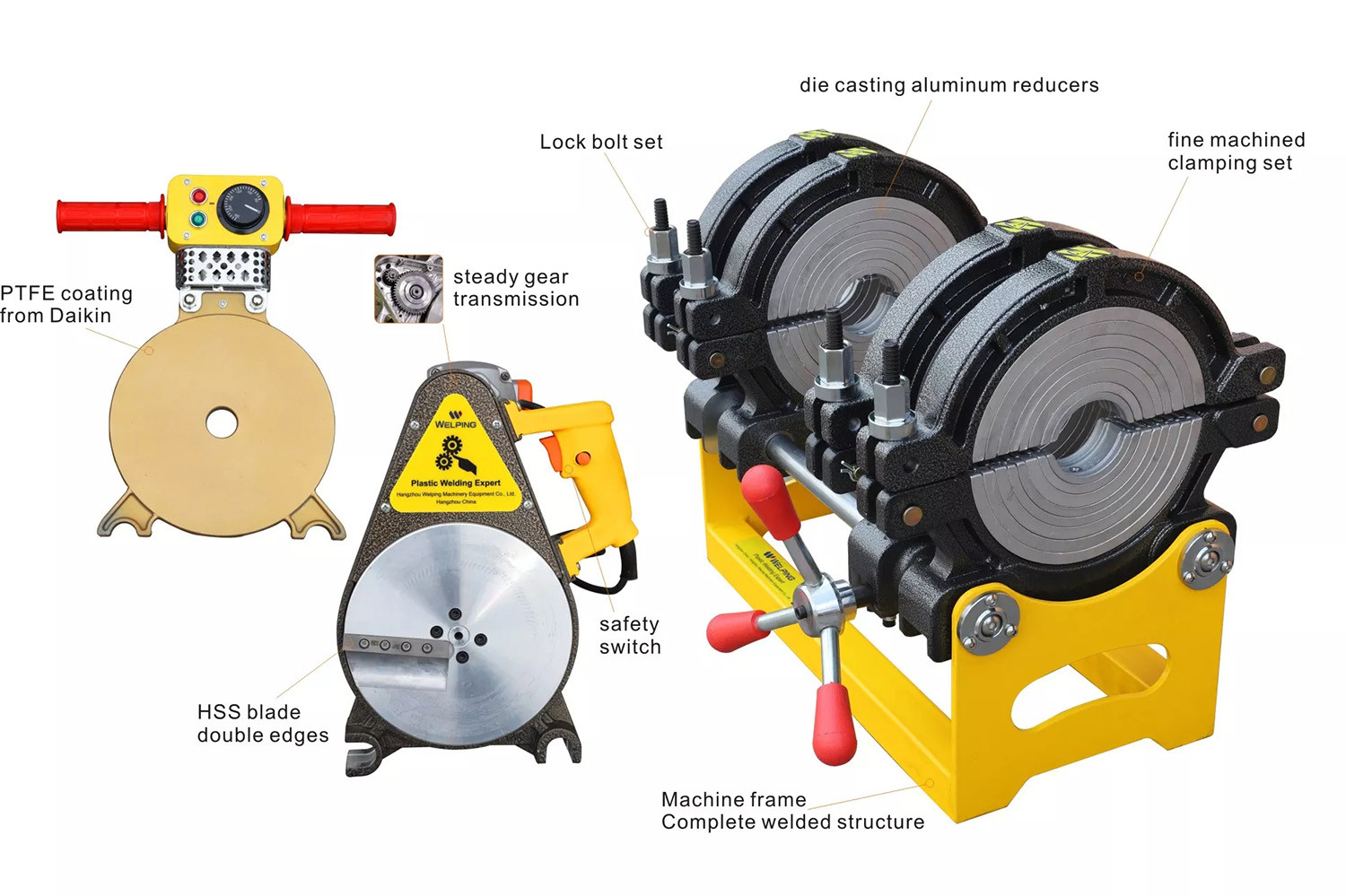

Manual HDPE Pipe Jointing Machine provides standard welding range of 63mm to 160mm, with unique gear transmission structure. mainly consists of 2 major parts: Carriage (also called frame or base), planing tool (also called trimmer or facer) and heater. Carriage for precise face joint and steady pipe clamping, planing tool and heater responsible for accurate trimming and heating. It's an effective, trouble free connecting for PE, PP, PVDF pipes.

FEATURES

※ Robust structure of carriage part with streamline outlook

※ Swivel handle with gear transmission of extremely smooth operating structure

※ Durable copper wiring motor, HSS blade, PTFE coating from Dupont or Daikin

STANDARD ACCESSORIES |

|

|

Main Frame

|

1 Set

|

|

Heating Plate

|

1 Set

|

|

Trimmer

|

1 Set

|

|

Reducers

|

1 Set

|

Tool Box | 1 Set |

PARAMETER

|

Mode

|

WP160D

|

|

Suitable materials

|

PE,PP, PB. PVDF

|

|

Range

|

63-75-90-110-125-140-160mm

|

|

Power supply

|

110V/220V

|

Frequency | 50HZ |

Total power | 2.6 KW |

Heating plate | 1.5 KW |

Planing tool | 1.1 KW |

Max.Temperature of heating plate | 270ºC |

Temp.Deviation in Surface | ±5ºC |

Total Weight | 47kg |

Net weight | 40kg |

Packing Size | 67**41*50cm |

PRODUCT DETAILS MAP

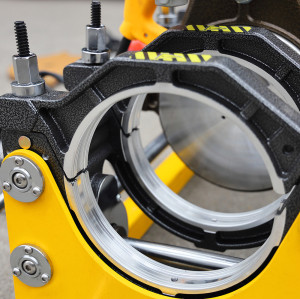

Basic Frame

· Complete welded frame structure, steady and robust

· Hand-wheel driving, simple and convenient

· Chromated integral shaft made of1045(ASTM)/S45C(JIS)/C45(DIN) steel

· Base made of Q235 steel with spraying treatment

· Cast aluminum clamps, sandblasting & Spraying treatment

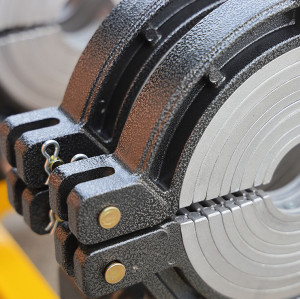

Planning tool

· HSS blade with double edge

· Casting aluminum trimmer plate, durable and anti-corrosion

· Gear transmission instead of chain

· Motor with pure copper wiring

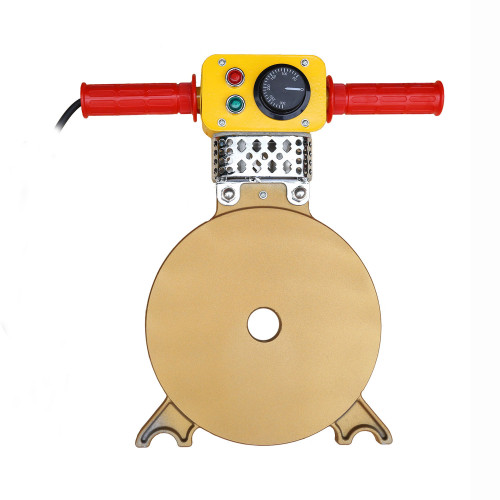

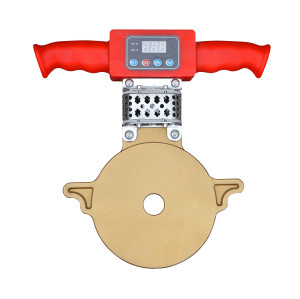

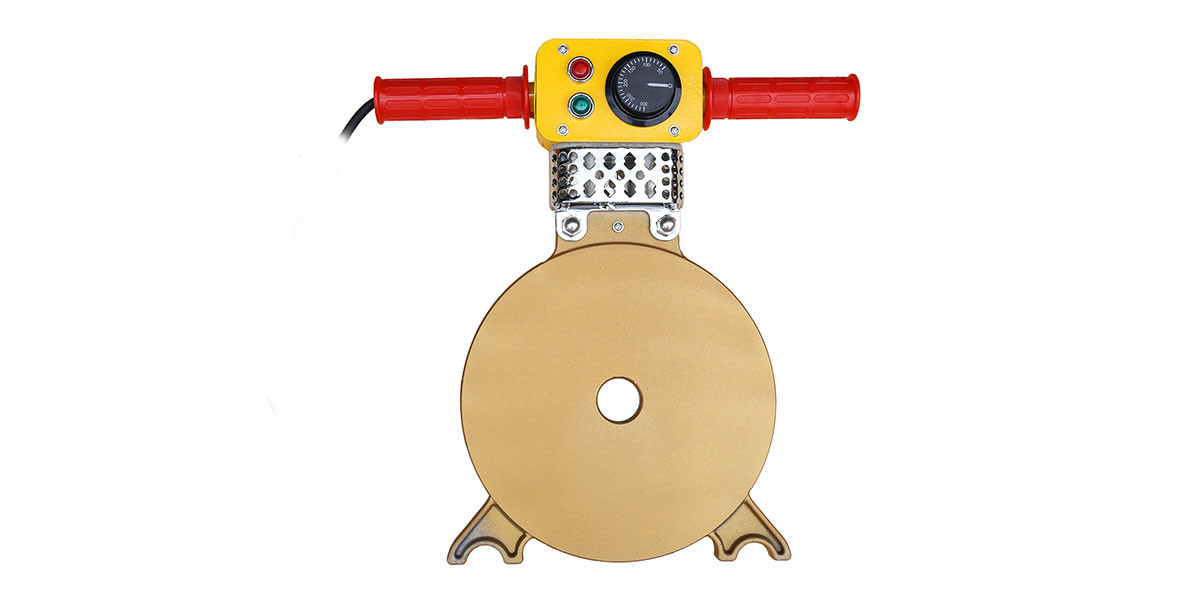

Heating Plate

· Teflon Coating from Japan

· Thermocouple sensor

· Bakelite handle

Reducers

63-75-90-110-125-140-160mm reducers

DOWNLOAD

WHAT WE CAN DO FOR YOU?

OUR SERVICES

WELPING develops, manufactures, and sells devices and systems for welding thermoplastics and, in this area, focuses consciously on pipeline systems as the main field of application. And We have been in this field for more than 17 years since 2005.

We aim to bring industrial level design, performance and quality together, to provide professional solutions for a variety of mining & industrial, marine, municipal, irrigation, energy and landfill to help you build reputation.

WELPING is committed to becoming a business for all thermoplastic pipe, which includes the fusion equipment and certified technical training to assist with the installation and fabrication of any plastic pipes related project. WELPING has continually broadened the scope of supply and usage for polyethylene pipe, valve, and fitting system design into new market segments. Also, We help our customers source pipe tools to support their projects. Our success is in the quality of our products and the knowledge and service of our people.